Page 573 - Subyek Computer Aided Design - [David Planchard] Engineering Design with SOLIDWORKS

P. 573

Engineering Design with SOLIDWORKS® 2018 Top-Down and Sheet Metal Parts

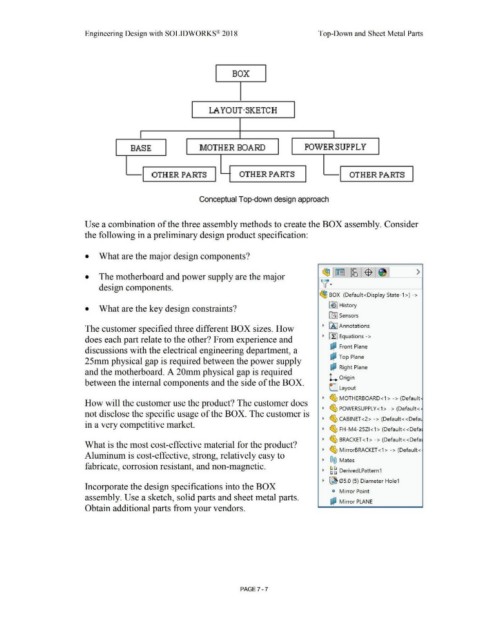

BOX

LA YOUT·SKETCH

BASE MOTHER BOARD POWER SUPPLY

OTHER PARTS OTHER PARTS OTHER PARTS

Conceptual Top-down design approach

Use a combination of the three assembly methods to create the BOX assembly. Consider

the following in a preliminary design product specification:

• What are the major design components?

>

• The motherboard and power supply are the major

design components. -

~ BOX (Default <Display State- 1 >) - >

• What are the key design constraints? ~ I History

t0:I Sensors

The customer specified three different BOX sizes. How • IA] Annotations

does each part relate to the other? From experience and • ~ Equations->

i:JJ Front Plane

discussions with the electrical engineering department, a '

c? Top Plane

25mm physical gap is required between the power supply

i:;? Right Plane

and the motherboard. A 20mm physical gap is required

L Origin

between the internal components and the side of the BOX.

L Layout

• ~ MOTHERBOARD<1 > -> (Default·

How will the customer use the product? The customer does

• ~ POWERSUPPLY<1> -> (Default<·

not disclose the specific usage of the BOX. The customer is

• ~ CABINET <2> -> (Default< <Defa1

in a very competitive market.

• ~ FH-M4-25Zl <1> (Default<<Defa

• ~ BRACKET <1 > - > (Default< <Defa

What is the most cost-effective material for the product?

• ~ MirrorBRACKET <1 > -> (Default <

Aluminum is cost-effective, strong, relatively easy to

• ®@ Mates

fabricate, corrosion resistant, and non-magnetic.

• ~ ~ DerivedLPattern1

• ~ 05.0 (5) Diameter Hole1

Incorporate the design specifications into the BOX

c, Mirror Point

assembly. Use a sketch, solid parts and sheet metal parts.

cP Mirror PLANE

Obtain additional parts from your vendors. '

PAGE 7 - 7