Page 897 - Industrial Power Engineering and Applications Handbook

P. 897

27/848 Industrial Power Engineering and Applications Handbook

27.3 Design criterion and I-+ ,

=1

characteristics of different MS tank

types of reactor Grounding

terminal

27.3.1 Air-cored or coreless type reactors

These reactors are made of copper winding without any

core, similar to an air-cored solenoid, as shown in Figure

27.3. In the absence of an iron core it causes a large Magnetic

amount of leakage flux in the space, which may also ,’- shield

infringe with the metallic tank housing the reactor, and

affect the reactance of the coil, in addition to heating the

tank itself. It is therefore important to provide some kind A Copper wound

of shielding between the winding of the reactor and the coil

tank. The shielding can be magnetic or non-magnetic as

discussed later. With shielding, the characteristics of an

air core reactor can be altered according to its application. ,,- Pressing plate

Such reactors provide linear I-$ characteristics in the

operating range, say, up to 150% of the rated current as

shown in Figure 27.2(a). In the absence of an iron core,

there is no saturation of the core. These reactors are y Tie rod

more useful when they are required to be used as current

limiting devices. But they reduce the steady-state power

transfer capability (V,’ /Z) of the system, as discussed in

Section 24.8.

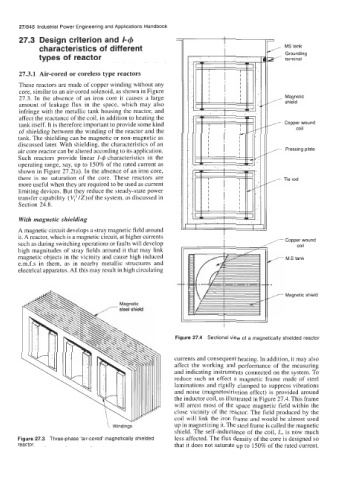

With magnetic shielding

A magnetic circuit develops a stray magnetic field around

it. A reactor, which is a magnetic circuit, at higher currents ,- wound

Copper

such as during switching operations or faults will develop coil

high magnitudes of stray fields around it that may link

magnetic objects in the vicinity and cause high induced M.S tank

e.m.f.s in them, as in nearby metallic structures and

electrical apparatus. All this may result in high circulating

t-

I I

I

Figure 27.4 Sectional view of a magnetically shielded reactor

currents and consequent heating. In addition, it may also

affect the working and performance of the measuring

and indicating instruments connected on the system. To

reduce such an effect a magnetic frame made of steel

laminations and rigidly clamped to suppress vibrations

and noise (magnetostriction effect) is provided around

the inductor coil, as illustrated in Figure 27.4. This frame

will arrest most of the space magnetic field within the

close vicinity of the reactor. The field produced by the

coil will link the iron frame and would be almost used

Windings up in magnetizing it. The steel frame is called the magnetic

shield. The self-inductance of the coil, L, is now much

Figure 27.3 Three-phase ‘air-cored’ magnetically shielded less affected. The flux density of the core is designed so

reactor that it does not saturate up to 150% of the rated current.