Page 987 - Industrial Power Engineering and Applications Handbook

P. 987

31/932 Industrial Power Engineering and Applications Handbook

Emclosure

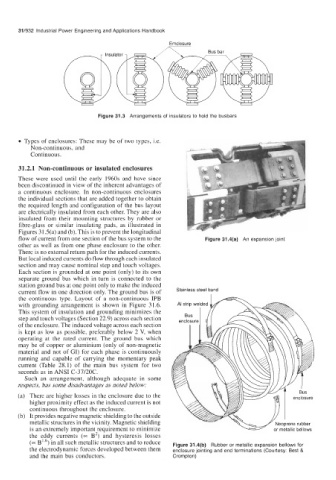

Figure 31.3 Arrangements of insulators to hold the busbars

Types of enclosures: These may be of two types, Le.

Non-continuous, and

Continuous.

31.2.1 Non-continuous or insulated enclosures

These were used until the early 1960s and have since

been discontinued in view of the inherent advantages of

a continuous enclosure. In non-continuous enclosures

the individual sections that are added together to obtain

the required length and configuration of the bus layout

are electrically insulated from each other. They are also

insulated from their mounting structures by rubber or

fibre-glass or similar insulating pads, as illustrated in

Figures 31.5(a) and (b). This is to prevent the longitudinal

flow of current from one section of the bus system to the Figure 31.4(a) An expansion joint

other as well as from one phase enclosure to the other.

There is no external return path for the induced currents.

But local induced currents do flow through each insulated

section and may cause nominal step and touch voltages.

Each section is grounded at one point (only) to its own

separate ground bus which in turn is connected to the

station ground bus at one point only to make the induced

current flow in one direction only. The ground bus is of Stainless steel band

the continuous type. Layout of a non-continuous IPB

with grounding arrangement is shown in Figure 3 1.6. AI strip we

This system of insulation and grounding minimizes the

step and touch voltages (Section 22.9) across each section

of the enclosure. The induced voltage across each section

is kept as low as possible, preferably below 2 V, when

operating at the rated current. The ground bus which

may be of copper or aluminium (only of non-magnetic

material and not of GI) for each phase is continuously

running and capable of carrying the momentary peak

current (Table 28.1) of the main bus system for two

seconds as in ANSI C-37/20C.

Such an arrangement, although adequate in some

respects, has some disadvantages as noted below:

(a) There are higher losses in the enclosure due to the

higher proximity effect as the induced current is not

continuous throughout the enclosure.

(b) It provides negative magnetic shielding to the outside

metallic structures in the vicinity. Magnetic shielding

is an extremely important requirement to minimize

the eddy currents (= B2) and hysteresis losses

(= B1'6) in structures and to reduce Figure 31.4(b) Rubber or metallic expansion bellows for

the electrodynamic forces developed between them enclosure jointing and end terminations (Courtesy: Best &

and the main bus conductors. Crompton)