Page 991 - Industrial Power Engineering and Applications Handbook

P. 991

31/936 Industrial Power Engineering and Applications Handbook

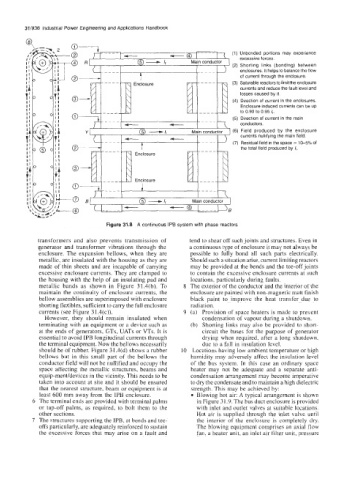

Unbonded portions may experience

excessive forces.

Shorting links (bonding) between

enclosures. It helps to balance the flow

of current through the enclosure.

Saturable reactors to limit the enclosure

currents and reduce the fault level and

losses caused by it.

Direction of current in the enclosures.

Enclosure induced currents can be up

to 0.90 to 0.95 I,.

Direction of current in the main

conductors.

Field produced by the enclosure

currents nuliifying the main field.

Residual field in the space = 1&5% of

the total field produced by C.

Figure 31.8 A continuous IPB system with phase reactors

transformers and also prevents transmission of tend to shear off such joints and structures. Even in

generator and transformer vibrations through- the a continuous type of enclosure it may not always be

enclosure. The expansion bellows, when they are possible to fully bond all such parts electrically.

metallic, are insulated with the housing as they are Should such a situation arise, current limiting reactors

made of thin sheets and are incapable of carrying may be provided at the bends and the tee-off joints

excessive enclosure currents. They are clamped to to contain the excessive enclosure currents at such

the housing with the help of an insulating pad and locations, particularly during faults.

metallic bands as shown in Figure 31.4(b). To 8 The exterior of the conductor and the interior of the

maintain the continuity of enclosure currents, the enclosure are painted with non-magnetic matt finish

bellow assemblies are superimposed with enclosure black paint to improve the heat transfer due to

shorting flefibles, sufficient to carry the full enclosure radiation.

currents (see Figure 3 1.4(c)). 9 (a) Provision of space heaters is made to prevent

However, they should remain insulated when condensation of vapour during a shutdown.

terminating with an equipment or a device such as (b) Shorting links may also be provided to short-

at the ends of generators, GTs, UATs or VTs. It is circuit the buses for the purpose of generator

essential to avoid IPB longitudinal currents through drying when required, after a long shutdown,

the terminal equipment. Now the bellows necessarily due to a fall in insulation level.

should be of rubber. Figure 31.4(d) shows a rubber IO Locations having low ambient temperature or high

bellows but in this small part of the bellows the humidity may adversely affect the insulation level

conductor field will not be nullified and occupy the of the bus system. In this case an ordinary space

space affecting the metallic structures, beams and heater may not be adequate and a separate anti-

equip-ment/devices in the vicinity. This needs to be condensation arrangement may become imperative

taken into account at site and it should be ensured to dry the condensate and to maintain a high dielectric

that the nearest structure, beam or equipment is at strength. This may be achieved by:

least 600 mm away from the IPB enclosure. Blowing hot air: A typical arrangement is shown

The terminal ends are provided with terminal palms in Figure 3 I .9. The bus duct enclosure is provided

or tap-off palms, as required, to bolt them to the with inlet and outlet valves at suitable locations.

other sections. Hot air is supplied through the inlet valve until

The structures supporting the IPB, at bends and tee- the interior of the enclosure is completely dry.

offs particularly, are adequately reinforced to sustain The blowing equipment comprises an axial flow

the excessive forces that may arise on a fault and fan, a heater unit, an inlet air filter unit, pressure