Page 998 - Industrial Power Engineering and Applications Handbook

P. 998

An isolated phase bus system 31/943

the generator transformer will be subject to a higher fault

level commensurate with the fault level of the power grid

limited upto the fault level of GT (Section 13.4.1.5 and

Figure 13.1 I ). Similarly. the tap-offs connecting the UATs

will be subject to a cumulative fault level. one of the

generator and the other of the power grid (limited up to

GT). Generally, therefore such large ratings ofbus systems

are subject to a high fault level. (For a few large ratings

!

of bus systems these lehels are shown in Table 13.8). Octagonal section ,A3

For ratings of 25000 A and above it is possible that

the fault level of the system may exceed the rupturing

capacity of the available interrupting devices. To reduce

the fault level in such cases, current limiting series reactors

can be provided with the bus system, as noted above and

illustrated in Figure 3 I .8.

Hexagonal section

31 .I 0 Voltage drop

As di~ussed earlier. this has no relevance in HT systems.

31.11 Forming sections for IPB

systems

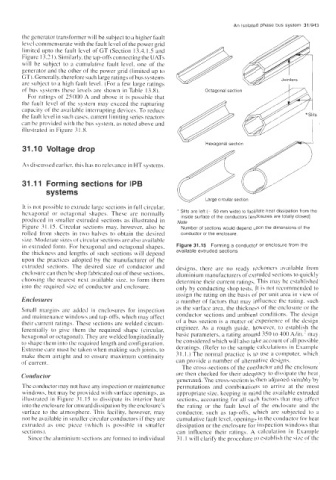

It is not possible to extrude large sections in full circular,

hexagonal or octagonal shapes. These are norinally * Slits are left (- 50 mm wide) to facilitate heat dissipation from the

inside surface of the conductors [enclosures are totally closed]

produced in smaller extruded sections as illustrated in Note

Figure 3 I. 15. Circular sections may, however, also be Number of sections would depend upon the dimensions of the

rolled from sheets in two halves to obtain the desired conductor or the enclosure

size. Moderate sizes of circular sections are also available

in extruded form. For hexagonal and octagonal shapes. Figure 31.15 Forming a conductor or enclosure from the

the thickness and lengths of such sections will depend available extruded sections

upon the practices adopted by the manufxturer of the

extruded sections. The desired size of conductor and designs, there are no ready reckoners available from

enclosure can then be shop fabricated out of these sections, aluminium manufacturers of extruded sections to quickly

choosing the nearest next available size. to form them determine their current ratings. This may be established

into the required sire of conductor and enclosure. only by conducting shop tests. It is not recommended to

assign the rating on the basis of per unit area in view of

Enclosures a number of factors that may influence the rating. such

Sinall margins are added in enclosures for inspection as the surface area, the thickness of the enclosure or the

and maintenance windows and tap-offs, which may affect conductor sections and ambient conditions. The design

their current ratings. These sections are welded circum- of a bus section is a matter of experience of the design

ferentially to give them the required shape (circular, engineer. As a rough guide, however. to establis,h the

hexagonal or octagonal). They are welded longitudinally basic parameters, a rating around 350 to 300 Ah- may

to shape them into the required length and configuration. be considered which will also take

Extreme care must be taken when making such joints, to deratings. (Refer to the sample calculations in Example

make them airtight and to ensure maximum continuity 3 1. I .) The normal practice is to use a computer. which

of current. can provide a number of alternative designs.

The cross-sections of the conductor and the enclosure

Conductor are then checked for their adequacy to dis-ipate the heat

generated. The cross-section is then adjusted suitably by

The conductor may not have any inspcction or maintenance permutations and combinations to arrive at the most

windows. but may be provided with surface openings, as appropriate size. keeping in mind the available extruded

illustrated in Figure 3 1.15 to dissipate its interior heat sections, accounting for all such factors that may affect

into the enclosure for onward dissipation by the enclosure’s the rating or the fault level of the enclosure and the

wrface to the atmosphere. This facility. however, may conductor. such as tap-offs. which are subjected to a

not be available in smaller circular conductors if they are cuinulative fault level, openings in the conductor for heat

extruded as one piece (which is possible in smaller dissipation or the enclosure for inspection windows that

sections). can influence their ratings. A calculation in Example

Since the alumini~im sections are formed to individual 3 I. I will clarify the procedure to establish the sire of the