Page 254 - Methods For Monitoring And Diagnosing The Efficiency Of Catalytic Converters A Patent - oriented Survey

P. 254

236 Methods for Monitoring and Diagnosing the Efficiency of Catalytic Converters

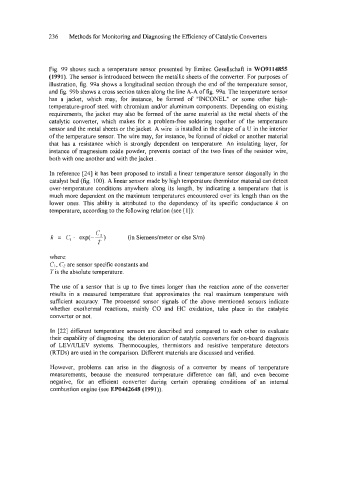

Fig. 99 shows such a temperature sensor presented by Emitec Gesellschafl in W09114855

(1991). The sensor is introduced between the metallic sheets of the converter. For purposes of

illustration, fig. 99a shows a longitudinal section through the end of the temperature sensor,

and fig. 99b shows a cross section taken along the line A-A of fig. 99a. The temperature sensor

has a jacket, which may, for instance, be formed of "INCONEL" or some other high-

temperature-proof steel with chromium and/or aluminum components. Depending on existing

requirements, the jacket may also be formed of the same material as the metal sheets of the

catalytic converter, which makes for a problem-free soldering together of the temperature

sensor and the metal sheets or the jacket. A wire is installed in the shape of a U in the interior

of the temperature sensor. The wire may, for instance, be formed of nickel or another material

that has a resistance which is strongly dependent on temperature. An insulating layer, for

instance of magnesium oxide powder, prevents contact of the two lines of the resistor wire,

both with one another and with the jacket .

In reference [24] it has been proposed to install a linear temperature sensor diagonally in the

catalyst bed (fig. 100). A linear sensor made by high temperature thermistor material can detect

over-temperature conditions anywhere along its length, by indicating a temperature that is

much more dependent on the maximum temperatures encountered over its length than on the

lower ones. This ability is attributed to the dependency of its specific conductance k on

temperature, according to the following relation (see [I]):

k = C, . exp(--) c, (in Siemendmeter or else S/m)

T

where:

C,, C2 are sensor specific constants and

Tis the absolute temperature.

The use of a sensor that is up to five times longer than the reaction zone of the converter

results in a measured temperature that approximates the real maximum temperature with

sufficient accuracy. The processed sensor signals of the above mentioned sensors indicate

whether exothermal reactions, mainly CO and HC oxidation, take place in the catalytic

converter or not.

In [22] different temperature sensors are described and compared to each other to evaluate

their capability of diagnosing the deterioration of catalytic converters for on-board diagnosis

of LEVRJLEV systems. Thermocouples, thermistors and resistive temperature detectors

(RTDs) are used in the comparison. Different materials are discussed and verified.

However, problems can arise in the diagnosis of a converter by means of temperature

measurements, because the measured temperature difference can fall, and even become

negative, for an efficient converter during certain operating conditions of an internal

combustion engine (see Em442648 (1991)).