Page 201 - Plant design and economics for chemical engineers

P. 201

COST ESTIMATION 175

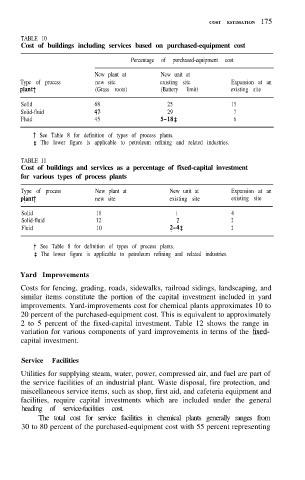

TABLE 10

Cost of buildings including services based on purchased-equipment cost

Percentage of purchased-equipment cost

New plant at New unit at

Type of process new site existing site Expansion at an

Plaw (Grass roots) (Battery limit) existing site

Solid 68 25 15

Solid-fluid 41 29 7

Fluid 45 5-18$ 6

t See Table 8 for definition of types of process plants.

$ The lower figure is applicable to petroleum refining and related industries.

TABLE 11

Cost of buildings and services as a percentage of fixed-capital investment

for various types of process plants

Type of process New plant at New unit at Expansion at an

plantt new site existing site existing site

Solid 18 1 4

Solid-fluid 12 7 2

Fluid 10 2-4% 2

t See Table 8 for definition of types of process plants.

$ The lower figure is applicable to petroleum refining and related industries.

Yard Improvements

Costs for fencing, grading, roads, sidewalks, railroad sidings, landscaping, and

similar items constitute the portion of the capital investment included in yard

improvements. Yard-improvements cost for chemical plants approximates 10 to

20 percent of the purchased-equipment cost. This is equivalent to approximately

2 to 5 percent of the fixed-capital investment. Table 12 shows the range in

variation for various components of yard improvements in terms of the fixed-

capital investment.

Service Facilities

Utilities for supplying steam, water, power, compressed air, and fuel are part of

the service facilities of an industrial plant. Waste disposal, fire protection, and

miscellaneous service items, such as shop, first aid, and cafeteria equipment and

facilities, require capital investments which are included under the general

heading of service-facilities cost.

The total cost for service facilities in chemical plants generally ranges from

30 to 80 percent of the purchased-equipment cost with 55 percent representing