Page 208 - Plant design and economics for chemical engineers

P. 208

182 PLANT DESIGN AND ECONOMICS FOR CHEMICAL ENGINEERS

investment. This is summarized in the following cost equation:

c, = [= + UfIE +f*E +f& + . ..~l~f.> (3)

where f,,fi...= multiplying factors for piping, electrical, instrumentation, etc.

fi = indirect cost factor always greater than 1.

The percentages used in making an estimation of this type should be

determined on the basis of the type of process involved, design complexity,

required materials of construction, location of the plant, past experience, and

other items dependent on the particular unit under consideration. Average

values of the various percentages have been determined for typical chemical

plants, and these values are presented in Table 17.

Estimating by percentage of delivered-equipment cost is comma ly used

for preliminary and study estimates. It yields most accurate results whe applied

to projects similar in configuration to recently constructed plants. For c mpara-

i

ble plants of different capacity, this method has sometimes been reported to

yield definitive estimate accuracies.

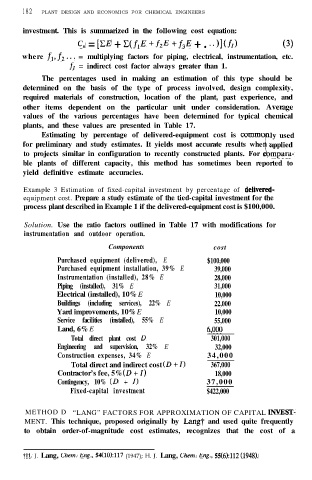

Example 3 Estimation of fixed-capital investment by percentage of delivered-

equipment cost. Prepare a study estimate of the tied-capital investment for the

process plant described in Example 1 if the delivered-equipment cost is $100,000.

Solution. Use the ratio factors outlined in Table 17 with modifications for

instrumentation and outdoor operation.

Components cost

Purchased equipment (delivered), E $100,000

Purchased equipment installation, 39% E 39,000

Instrumentation (installed), 28% E 28,000

Piping (installed), 31% E 31,000

Electrical (installed), 10% E 10,000

Buildings (including services), 22% E 22,000

Yard improvements, 10% E 10,000

Service facilities (installed), 55% E 55,000

Land, 6% E 6,000

Total direct plant cost D 301,000

Engineering and supervision, 32% E 32,000

Construction expenses, 34% E 34,000

Total direct and indirect cost (D + I) 367,000

Contractor’s fee, 5% (D + I) 18,000

Contingency, 10% (D + I) 37,000

Fixed-capital investment $422,000

METHOD D “LANG” FACTORS FOR APPROXIMATION OF CAPITAL INVFST-

MENT. This technique, proposed originally by Lang-/’ and used quite frequently

to obtain order-of-magnitude cost estimates, recognizes that the cost of a

tH. J. Lang, Chem. Eng., 54(10):117 (1947); H. J. Lang, Chem. Eng., 55(6):112 (1948).