Page 479 - Rock Mechanics For Underground Mining

P. 479

SUBLEVEL CAVING

From these and other equations, design charts may be prepared to assist in eval-

uating alternative layouts in a given case. Chatterjee et al. (1974, 1979) extended

this analysis to permit digital simulations of complete sublevel caving systems to be

carried out.

If the slice width, A, is determined from inequality 15.13 or from the results of a

simulation or a field trial, the trial pillar width is given as

P = A − B (15.14)

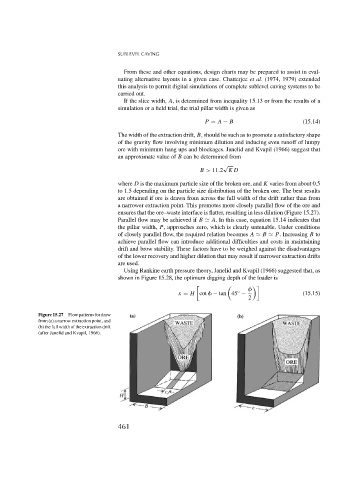

The width of the extraction drift, B, should be such as to promote a satisfactory shape

of the gravity flow involving minimum dilution and inducing even runoff of lumpy

ore with minimum hang ups and blockages. Janelid and Kvapil (1966) suggest that

an approximate value of B can be determined from

√

B > 11.2 KD

where D is the maximum particle size of the broken ore, and K varies from about 0.5

to 1.5 depending on the particle size distribution of the broken ore. The best results

are obtained if ore is drawn from across the full width of the drift rather than from

a narrower extraction point. This promotes more closely parallel flow of the ore and

ensures that the ore–waste interface is flatter, resulting in less dilution (Figure 15.27).

Parallel flow may be achieved if B A. In this case, equation 15.14 indicates that

the pillar width, P, approaches zero, which is clearly untenable. Under conditions

of closely parallel flow, the required relation becomes A B P. Increasing B to

achieve parallel flow can introduce additional difficulties and costs in maintaining

drift and brow stability. These factors have to be weighed against the disadvantages

of the lower recovery and higher dilution that may result if narrower extraction drifts

are used.

Using Rankine earth pressure theory, Janelid and Kvapil (1966) suggested that, as

shown in Figure 15.28, the optimum digging depth of the loader is

◦

x = H cot − tan 45 − (15.15)

2

Figure15.27 Flowpatternsfordraw

from (a) a narrow extraction point, and

(b) the full width of the extraction drift

(after Janelid and Kvapil, 1966).

461