Page 67 - Mechanical Behavior of Materials

P. 67

68 Chapter 3 A Survey of Engineering Materials

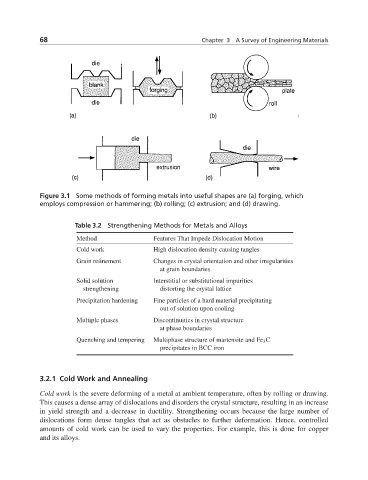

Figure 3.1 Some methods of forming metals into useful shapes are (a) forging, which

employs compression or hammering; (b) rolling; (c) extrusion; and (d) drawing.

Table 3.2 Strengthening Methods for Metals and Alloys

Method Features That Impede Dislocation Motion

Cold work High dislocation density causing tangles

Grain refinement Changes in crystal orientation and other irregularities

at grain boundaries

Solid solution Interstitial or substitutional impurities

strengthening distorting the crystal lattice

Precipitation hardening Fine particles of a hard material precipitating

out of solution upon cooling

Multiple phases Discontinuities in crystal structure

at phase boundaries

Quenching and tempering Multiphase structure of martensite and Fe 3 C

precipitates in BCC iron

3.2.1 Cold Work and Annealing

Cold work is the severe deforming of a metal at ambient temperature, often by rolling or drawing.

This causes a dense array of dislocations and disorders the crystal structure, resulting in an increase

in yield strength and a decrease in ductility. Strengthening occurs because the large number of

dislocations form dense tangles that act as obstacles to further deformation. Hence, controlled

amounts of cold work can be used to vary the properties. For example, this is done for copper

and its alloys.