Page 94 - Mechanical Behavior of Materials

P. 94

Section 3.6 Ceramics and Glasses 95

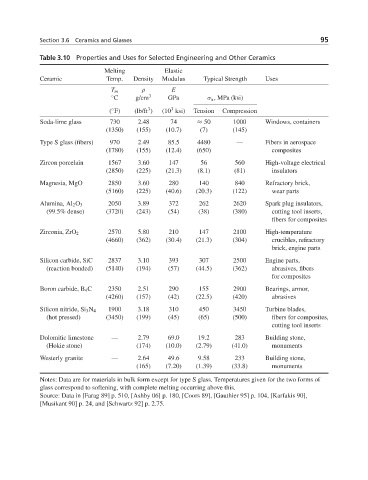

Table 3.10 Properties and Uses for Selected Engineering and Other Ceramics

Melting Elastic

Ceramic Temp. Density Modulus Typical Strength Uses

T m ρ E

◦ C g/cm 3 GPa σ u ,MPa (ksi)

3

3

( F) (lb/ft ) (10 ksi) Tension Compression

◦

Soda-lime glass 730 2.48 74 ≈ 50 1000 Windows, containers

(1350) (155) (10.7) (7) (145)

Type S glass (fibers) 970 2.49 85.5 4480 — Fibers in aerospace

(1780) (155) (12.4) (650) composites

Zircon porcelain 1567 3.60 147 56 560 High-voltage electrical

(2850) (225) (21.3) (8.1) (81) insulators

Magnesia, MgO 2850 3.60 280 140 840 Refractory brick,

(5160) (225) (40.6) (20.3) (122) wear parts

Alumina, Al 2 O 3 2050 3.89 372 262 2620 Spark plug insulators,

(99.5% dense) (3720) (243) (54) (38) (380) cutting tool inserts,

fibers for composites

2570 5.80 210 147 2100 High-temperature

Zirconia, ZrO 2

(4660) (362) (30.4) (21.3) (304) crucibles, refractory

brick, engine parts

Silicon carbide, SiC 2837 3.10 393 307 2500 Engine parts,

(reaction bonded) (5140) (194) (57) (44.5) (362) abrasives, fibers

for composites

Boron carbide, B 4 C 2350 2.51 290 155 2900 Bearings, armor,

(4260) (157) (42) (22.5) (420) abrasives

Silicon nitride, Si 3 N 4 1900 3.18 310 450 3450 Turbine blades,

(hot pressed) (3450) (199) (45) (65) (500) fibers for composites,

cutting tool inserts

Dolomitic limestone — 2.79 69.0 19.2 283 Building stone,

(Hokie stone) (174) (10.0) (2.79) (41.0) monuments

Westerly granite — 2.64 49.6 9.58 233 Building stone,

(165) (7.20) (1.39) (33.8) monuments

Notes: Data are for materials in bulk form except for type S glass. Temperatures given for the two forms of

glass correspond to softening, with complete melting occurring above this.

Source: Data in [Farag 89] p. 510, [Ashby 06] p. 180, [Coors 89], [Gauthier 95] p. 104, [Karfakis 90],

[Musikant 90] p. 24, and [Schwartz 92] p. 2.75.