Page 133 - Introduction to Marine Engineering

P. 133

Pumps and pumping systems 119

is equivalent to a low lift centrifugal pump and the higher speeds

possible enable a smaller driving motor to be used. The axial-flow pump

is also suitable for supplementary use in a condenser scoop circulating

system since the pump will offer little resistance to flow when idling.

With scoop circulation the normal movement of the ship will draw in

water; the pump would be in use only when the ship was moving slowly

or stopped.

Centrifugal pump

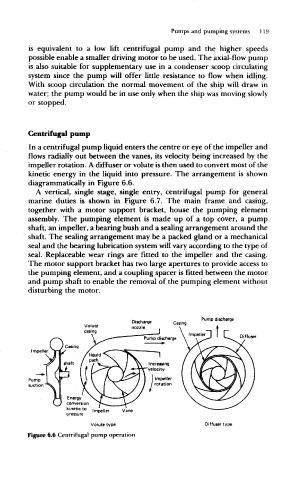

In a centrifugal pump liquid enters the centre or eye of the impeller and

flows radially out between the vanes, its velocity being increased by the

impeller rotation. A diffuser or volute is then used to convert most of the

kinetic energy in the liquid into pressure. The arrangement is shown

diagrammatically in Figure 6.6.

A vertical, single stage, single entry, centrifugal pump for general

marine duties is shown in Figure 6.7. The main frame and casing,

together with a motor support bracket, house the pumping element

assembly. The pumping element is made up of a top cover, a pump

shaft, an impeller, a bearing bush and a sealing arrangement around the

shaft. The sealing arrangement may be a packed gland or a mechanical

seal and the bearing lubrication system will vary according to the type of

seal. Replaceable wear rings are fitted to the impeller and the casing.

The motor support bracket has two large apertures to provide access to

the pumping element, and a coupling spacer is fitted between the motor

and pump shaft to enable the removal of the pumping element without

disturbing the motor.

Pump discharge

Volute

casing

Diffuser

Casing

impeller

shaft increasing

velocity

I Impeller

/ rotation

Energy

conversion

kinetic to |mpe)|er v ), ne

pressure

Volute type Oiffuser type

Figure 6.6 Centrifugal pump operation