Page 170 - Introduction to Marine Engineering

P. 170

156 Fuel oils, lubricating oils and their treatment

Continuous operation

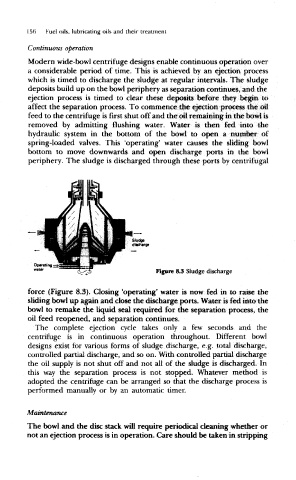

Modern wide-bowl centrifuge designs enable continuous operation over

a considerable period of time. This is achieved by an ejection process

which is timed to discharge the sludge at regular intervals. The sludge

deposits build up on the bowl periphery as separation continues, and the

ejection process is timed to clear these deposits before they begin, to

affect the separation process. To commence the ejection process the oil

feed to the centrifuge is first shut off and the oil remaining in the bowl is

removed by admitting flushing water. Water is then fed into the

hydraulic system in the bottom of the bowl to open a number of

spring-loaded valves. This 'operating' water causes the sliding bowl

bottom to move downwards and open discharge ports in the bowl

periphery. The sludge is discharged through these ports by centrifugal

Figure 8.3 Sludge discharge

force (Figure 8.3). Closing 'operating' water is now fed in to raise the

sliding bowl up again and close the discharge ports. Water is fed into the

bowl to remake the liquid seal required for the separation process, the

oil feed reopened, and separation continues.

The complete ejection cycle takes only a few seconds and the

centrifuge is in continuous operation throughout. Different bowl

designs exist for various forms of sludge discharge, e.g. total discharge,

controlled partial discharge, and so on. With controlled partial discharge

the oil supply is not shut off and not all of the sludge is discharged. In

this way the separation process is not stopped. Whatever method is

adopted the centrifuge can be arranged so that the discharge process is

performed manually or by an automatic timer.

Maintenance

The bowl and the disc stack will require periodical cleaning whether or

not an ejection process is in operation. Care should be taken in stripping