Page 199 - Introduction to Marine Engineering

P. 199

184 Deck machinery and hull equipment

particularly on larger vessels, is the split windlass where one machine is

used for each anchor.

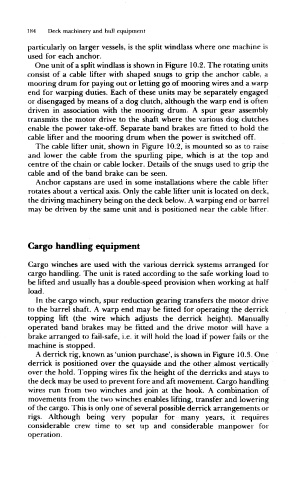

One unit of a split windlass is shown in Figure 10.2. The rotating units

consist of a cable lifter with shaped snugs to grip the anchor cable, a

mooring drum for paying out or letting go of mooring wires and a warp

end for warping duties. Each of these units may be separately engaged

or disengaged by means of a dog clutch, although the warp end is often

driven in association with the mooring drum. A spur gear assembly

transmits the motor drive to the shaft where the various dog clutches

enable the power take-off. Separate band brakes are fitted to hold the

cable lifter and the mooring drum when the power is switched off.

The cable lifter unit, shown in Figure 10.2, is mounted so as to raise

and lower the cable from the spurling pipe, which is at the top and

centre of the chain or cable locker. Details of the snugs used to grip the

cable and of the band brake can be seen.

Anchor capstans are used in some installations where the cable lifter

rotates about a vertical axis. Only the cable lifter unit is located on deck,

the driving machinery being on the deck below. A warping end or barrel

may be driven by the same unit and is positioned near the cable lifter.

Cargo handling equipment

Cargo winches are used with the various derrick systems arranged for

cargo handling. The unit is rated according to the safe working load to

be lifted and usually has a double-speed provision when working at half

load.

In the cargo winch, spur reduction gearing transfers the motor drive

to the barrel shaft. A warp end may be Fitted for operating the derrick

topping lift (the wire which adjusts the derrick height). Manually

operated band brakes may be fitted and the drive motor will have a

brake arranged to fail-safe, i.e. it will hold the load if power fails or the

machine is stopped.

A derrick rig, known as 'union purchase', is shown in Figure 10.3. One

derrick is positioned over the quayside and the other almost vertically

over the hold. Topping wires fix the height of the derricks and stays to

the deck may be used to prevent fore and aft movement. Cargo handling

wires run from two winches and join at the hook. A combination of

movements from the two winches enables lifting, transfer and lowering

of the cargo. This is only one of several possible derrick arrangements or

rigs. Although being very popular for many years, it requires

considerable crew time to set up and considerable manpower for

operation.