Page 73 - Introduction to Marine Engineering

P. 73

60 Steam turbines and gearing

One method of achieving this balance is the use of a dummy piston

and cylinder. A pipe from some stage in the turbine provides steam to

act on the dummy piston which is mounted on the turbine rotor (Figure

3.7). The rotor casing provides the cylinder to enable the steam pressure

to create an axial force on the turbine shaft. The dummy piston annular

area and the steam pressure are chosen to produce a force which exactly

balances the end thrust from the reaction blading. A turbine with ahead

and astern blading will have a dummy piston at either end to ensure

balance in either direction of rotation.

Another method often used in low-pressure turbines is to make the

turbine double flow. With this arrangement steam enters at the centre of

the shaft and flows along in opposite directions. With an equal division

of steam the two reaction effects balance and cancel one another.

Glands and gland sealing

Steam is prevented from leaking out of the rotor high-pressure end and

air is prevented from entering the low-pressure end by the use of glands.

A combination of mechanical glands and a gland sealing system is usual.

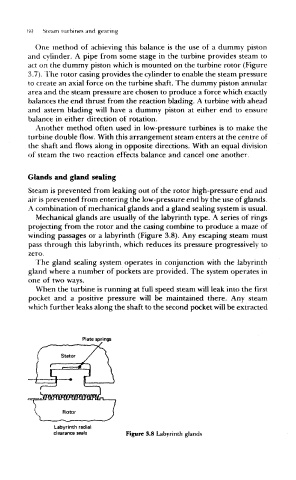

Mechanical glands are usually of the labyrinth type. A series of rings

projecting from the rotor and the casing combine to produce a maze of

winding passages or a labyrinth (Figure 3.8). Any escaping steam must

pass through this labyrinth, which reduces its pressure progressively to

zero.

The gland sealing system operates in conjunction with the labyrinth

gland where a number of pockets are provided. The system operates in

one of two ways.

When the turbine is running at full speed steam will leak into the first

pocket and a positive pressure will be maintained there. Any steam

which further leaks along the shaft to the second pocket will be extracted

Plate springs

Labyrinth radial

clearance seals Figure 3.8 Labyrinth glands