Page 117 - Moving the Earth_ The Workbook of Excavation

P. 117

ROCK, SOIL, AND MUD

ROCK, SOIL, AND MUD 3.11

COMPACTION

The term “compaction” refers to the act of artificially increasing the density of soil. It involves

the pressing of soil particles together into closer contact, and expelling air or water from spaces

between them.

When the same process occurs in nature, as a result of wetting, drying, freezing, thawing,

groundwater movement, and weight of higher soil layers, it is called settlement.

The density of soil is measured in terms of its volume-weight, which may be expressed as pounds

of wet soil or dry soil per cubic foot, or as porosity in percent of total volume. A high porosity

indicates a low density.

The purpose of compaction is to stabilize soil, particularly in built-up fills, embankments, and

dams, so that it will show minimum change in volume or shape under influences of weather and time,

and under the weight of structures, pavement, and traffic.

Compaction is also useful or necessary to the work of building a fill. Loose soil causes haulers

to use excessive power, break drivetrain parts, and get stuck. Rain that would wet only the surface

of a compacted fill might sink into a loose one far enough to create several feet of impassable mud

that would stop the work.

Background. The desirability of compacting road fills has been recognized since ancient times.

Early methods included driving sheep or cattle back and forth on the fill, and towing weighted

wooden rollers with horses.

Reliance on natural settlement and/or simple rule-of-thumb compaction methods is becoming

impractical, because of the increasing loads carried by the modern highway. There is constant

pressure to revise state and federal laws to permit heavier axle and gross loads, in spite of the fact

that the bearing capacity of ordinary soils has already been reached and exceeded in many areas.

Equipment. Compaction equipment is described in Chap. 19.

Soil may be compacted by pressure, kneading, vibration, impact, or combinations. The steel

wheel and sheepsfoot rollers supply pressure, pneumatic tire rollers supply pressure with some

kneading, wobble-wheel rollers supply kneading and pressure, and vibratory rollers supply both

pressure and vibration.

Steel wheel rollers give good results on all types of soil except clean sands, in layers from 4 to 12

inches deep depending on soil type and roller weight. Clay soil layers should be limited to 4 to 6 inches,

to avoid possible compaction of the top of the layer only.

Sheepsfoot rollers compact mostly with the soles of their feet, from the bottom up. As the soil

is compacted, the roller rises and walks out of the ground. They do best on fine-grained soils of the

plastic groups, and are least efficient in sandy and gravelly types. Excessive weight may have to

be avoided, as the feet may shear soil and damage its structure.

Rubber tire rollers are suitable for use in any type of soil, but weight and tire pressure must be

proper for the soil type. Results are affected by shape of tires and their air pressure and by total

wheel or axle load, not by tire pressure only, as is often supposed.

Vibration is most effective in sand or gravel soils, but may increase the effectiveness of a roller

in any soil. It is particularly effective at bringing excess moisture to the surface.

Trench fills and other small areas may be compacted by impact of air, hydraulic, or gasoline

hammers, or vibrators. Gravel fills may be compacted by puddling—adding water until the soil is

semiliquid—then allowing it to dry and settle. An immersion (concrete) vibrator will speed drying

of puddled fill, by bringing its water to the surface.

Moisture Content. The most critical factor in compaction of a soil is its moisture content, since

it can be most thoroughly and conveniently compacted only if it contains just the right amount of

water. This quantity is called the optimum moisture content. It must be sufficient to provide a

lubricant to allow soil grains to slide on each other as they are pushed together, and not enough

to form an incompressible cushion between any of them.

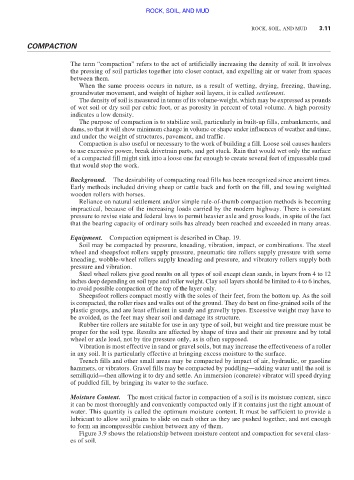

Figure 3.9 shows the relationship between moisture content and compaction for several class-

es of soil.