Page 149 - Moving the Earth_ The Workbook of Excavation

P. 149

ROCK, SOIL, AND MUD

ROCK, SOIL, AND MUD 3.43

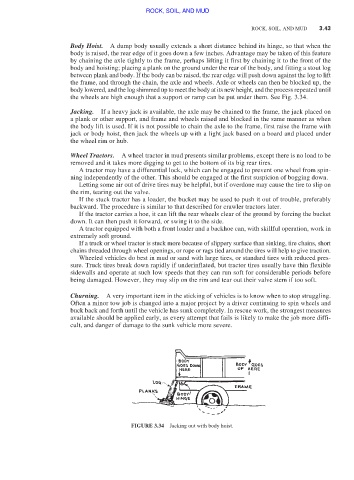

Body Hoist. A dump body usually extends a short distance behind its hinge, so that when the

body is raised, the rear edge of it goes down a few inches. Advantage may be taken of this feature

by chaining the axle tightly to the frame, perhaps lifting it first by chaining it to the front of the

body and hoisting; placing a plank on the ground under the rear of the body, and fitting a stout log

between plank and body. If the body can be raised, the rear edge will push down against the log to lift

the frame, and through the chain, the axle and wheels. Axle or wheels can then be blocked up, the

body lowered, and the log shimmed up to meet the body at its new height, and the process repeated until

the wheels are high enough that a support or ramp can be put under them. See Fig. 3.34.

Jacking. If a heavy jack is available, the axle may be chained to the frame, the jack placed on

a plank or other support, and frame and wheels raised and blocked in the same manner as when

the body lift is used. If it is not possible to chain the axle to the frame, first raise the frame with

jack or body hoist, then jack the wheels up with a light jack based on a board and placed under

the wheel rim or hub.

Wheel Tractors. A wheel tractor in mud presents similar problems, except there is no load to be

removed and it takes more digging to get to the bottom of its big rear tires.

A tractor may have a differential lock, which can be engaged to prevent one wheel from spin-

ning independently of the other. This should be engaged at the first suspicion of bogging down.

Letting some air out of drive tires may be helpful, but if overdone may cause the tire to slip on

the rim, tearing out the valve.

If the stuck tractor has a loader, the bucket may be used to push it out of trouble, preferably

backward. The procedure is similar to that described for crawler tractors later.

If the tractor carries a hoe, it can lift the rear wheels clear of the ground by forcing the bucket

down. It can then push it forward, or swing it to the side.

A tractor equipped with both a front loader and a backhoe can, with skillful operation, work in

extremely soft ground.

If a truck or wheel tractor is stuck more because of slippery surface than sinking, tire chains, short

chains threaded through wheel openings, or rope or rags tied around the tires will help to give traction.

Wheeled vehicles do best in mud or sand with large tires, or standard tires with reduced pres-

sure. Truck tires break down rapidly if underinflated, but tractor tires usually have thin flexible

sidewalls and operate at such low speeds that they can run soft for considerable periods before

being damaged. However, they may slip on the rim and tear out their valve stem if too soft.

Churning. A very important item in the sticking of vehicles is to know when to stop struggling.

Often a minor tow job is changed into a major project by a driver continuing to spin wheels and

buck back and forth until the vehicle has sunk completely. In rescue work, the strongest measures

available should be applied early, as every attempt that fails is likely to make the job more diffi-

cult, and danger of damage to the sunk vehicle more severe.

FIGURE 3.34 Jacking out with body hoist.