Page 211 - Moving the Earth_ The Workbook of Excavation

P. 211

DITCHING AND DEWATERING

DITCHING AND DEWATERING 5.13

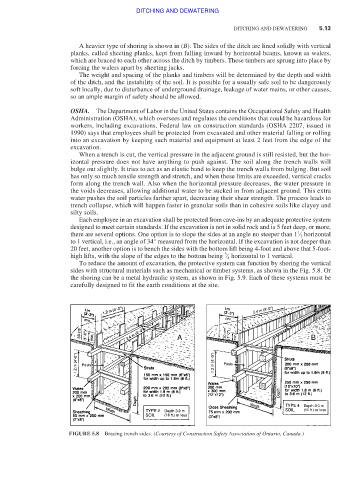

A heavier type of shoring is shown in (B). The sides of the ditch are lined solidly with vertical

planks, called sheeting planks, kept from falling inward by horizontal beams, known as walers,

which are braced to each other across the ditch by timbers. These timbers are sprung into place by

forcing the walers apart by sheeting jacks.

The weight and spacing of the planks and timbers will be determined by the depth and width

of the ditch, and the instability of the soil. It is possible for a usually safe soil to be dangerously

soft locally, due to disturbance of underground drainage, leakage of water mains, or other causes,

so an ample margin of safety should be allowed.

OSHA. The Department of Labor in the United States contains the Occupational Safety and Health

Administration (OSHA), which oversees and regulates the conditions that could be hazardous for

workers, including excavations. Federal law on construction standards (OSHA 2207, issued in

1990) says that employees shall be protected from excavated and other material falling or rolling

into an excavation by keeping such material and equipment at least 2 feet from the edge of the

excavation.

When a trench is cut, the vertical pressure in the adjacent ground is still resisted, but the hor-

izontal pressure does not have anything to push against. The soil along the trench walls will

bulge out slightly. It tries to act as an elastic band to keep the trench walls from bulging. But soil

has only so much tensile strength and stretch, and when these limits are exceeded, vertical cracks

form along the trench wall. Also when the horizontal pressure decreases, the water pressure in

the voids decreases, allowing additional water to be sucked in from adjacent ground. This extra

water pushes the soil particles farther apart, decreasing their shear strength. The process leads to

trench collapse, which will happen faster in granular soils than in cohesive soils like clayey and

silty soils.

Each employee in an excavation shall be protected from cave-ins by an adequate protective system

designed to meet certain standards. If the excavation is not in solid rock and is 5 feet deep, or more,

1

there are several options. One option is to slope the sides at an angle no steeper than 1 ⁄ 2 horizontal

to 1 vertical, i.e., an angle of 34° measured from the horizontal. If the excavation is not deeper than

20 feet, another option is to bench the sides with the bottom lift being 4-foot and above that 5-foot-

3

high lifts, with the slope of the edges to the bottom being ⁄ 4 horizontal to 1 vertical.

To reduce the amount of excavation, the protective system can function by shoring the vertical

sides with structural materials such as mechanical or timber systems, as shown in the Fig. 5.8. Or

the shoring can be a metal hydraulic system, as shown in Fig. 5.9. Each of these systems must be

carefully designed to fit the earth conditions at the site.

A B

FIGURE 5.8 Bracing trench sides. (Courtesy of Construction Safety Association of Ontario, Canada.)