Page 235 - Moving the Earth_ The Workbook of Excavation

P. 235

DITCHING AND DEWATERING

DITCHING AND DEWATERING 5.37

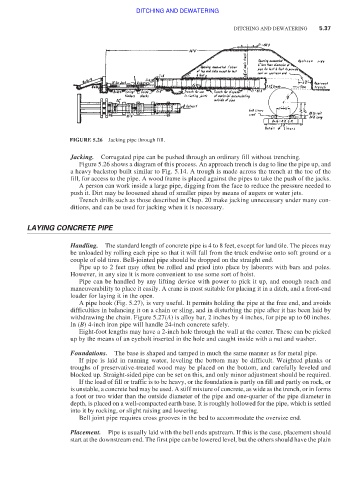

FIGURE 5.26 Jacking pipe through fill.

Jacking. Corrugated pipe can be pushed through an ordinary fill without trenching.

Figure 5.26 shows a diagram of this process. An approach trench is dug to line the pipe up, and

a heavy backstop built similar to Fig. 5.14. A trough is made across the trench at the toe of the

fill, for access to the pipe. A wood frame is placed against the pipes to take the push of the jacks.

A person can work inside a large pipe, digging from the face to reduce the pressure needed to

push it. Dirt may be loosened ahead of smaller pipes by means of augers or water jets.

Trench drills such as those described in Chap. 20 make jacking unnecessary under many con-

ditions, and can be used for jacking when it is necessary.

LAYING CONCRETE PIPE

Handling. The standard length of concrete pipe is 4 to 8 feet, except for land tile. The pieces may

be unloaded by rolling each pipe so that it will fall from the truck endwise onto soft ground or a

couple of old tires. Bell-jointed pipe should be dropped on the straight end.

Pipe up to 2 feet may often be rolled and pried into place by laborers with bars and poles.

However, in any size it is more convenient to use some sort of hoist.

Pipe can be handled by any lifting device with power to pick it up, and enough reach and

maneuverability to place it easily. A crane is most suitable for placing it in a ditch, and a front-end

loader for laying it in the open.

A pipe hook (Fig. 5.27), is very useful. It permits holding the pipe at the free end, and avoids

difficulties in balancing it on a chain or sling, and in disturbing the pipe after it has been laid by

withdrawing the chain. Figure 5.27(A) is alloy bar, 2 inches by 4 inches, for pipe up to 60 inches.

In (B) 4-inch iron pipe will handle 24-inch concrete safely.

Eight-foot lengths may have a 2-inch hole through the wall at the center. These can be picked

up by the means of an eyebolt inserted in the hole and caught inside with a nut and washer.

Foundations. The base is shaped and tamped in much the same manner as for metal pipe.

If pipe is laid in running water, leveling the bottom may be difficult. Weighted planks or

troughs of preservative-treated wood may be placed on the bottom, and carefully leveled and

blocked up. Straight-sided pipe can be set on this, and only minor adjustment should be required.

If the load of fill or traffic is to be heavy, or the foundation is partly on fill and partly on rock, or

is unstable, a concrete bed may be used. A stiff mixture of concrete, as wide as the trench, or in forms

a foot or two wider than the outside diameter of the pipe and one-quarter of the pipe diameter in

depth, is placed on a well-compacted earth base. It is roughly hollowed for the pipe, which is settled

into it by rocking, or slight raising and lowering.

Bell joint pipe requires cross grooves in the bed to accommodate the oversize end.

Placement. Pipe is usually laid with the bell ends upstream. If this is the case, placement should

start at the downstream end. The first pipe can be lowered level, but the others should have the plain