Page 252 - Moving the Earth_ The Workbook of Excavation

P. 252

DITCHING AND DEWATERING

5.54 THE WORK

FIGURE 5.44 Projecting drainage outlet.

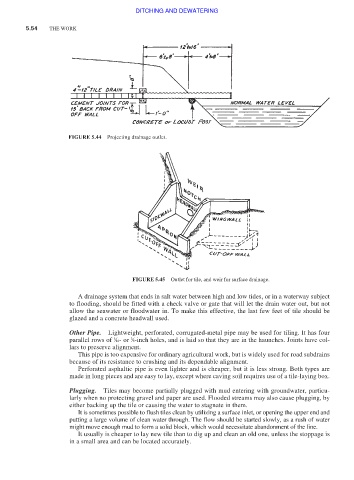

FIGURE 5.45 Outlet for tile, and weir for surface drainage.

A drainage system that ends in salt water between high and low tides, or in a waterway subject

to flooding, should be fitted with a check valve or gate that will let the drain water out, but not

allow the seawater or floodwater in. To make this effective, the last few feet of tile should be

glazed and a concrete headwall used.

Other Pipe. Lightweight, perforated, corrugated-metal pipe may be used for tiling. It has four

3

5

parallel rows of ⁄16- or ⁄8-inch holes, and is laid so that they are in the haunches. Joints have col-

lars to preserve alignment.

This pipe is too expensive for ordinary agricultural work, but is widely used for road subdrains

because of its resistance to crushing and its dependable alignment.

Perforated asphaltic pipe is even lighter and is cheaper, but it is less strong. Both types are

made in long pieces and are easy to lay, except where caving soil requires use of a tile-laying box.

Plugging. Tiles may become partially plugged with mud entering with groundwater, particu-

larly when no protecting gravel and paper are used. Flooded streams may also cause plugging, by

either backing up the tile or causing the water to stagnate in them.

It is sometimes possible to flush tiles clean by utilizing a surface inlet, or opening the upper end and

putting a large volume of clean water through. The flow should be started slowly, as a rush of water

might move enough mud to form a solid block, which would necessitate abandonment of the line.

It usually is cheaper to lay new tile than to dig up and clean an old one, unless the stoppage is

in a small area and can be located accurately.