Page 293 - Moving the Earth_ The Workbook of Excavation

P. 293

PONDS AND EARTH DAMS

This apparatus rests on a small block of concrete, which is cast around the edge of the drainpipe

and around tar paper wrapped around the end pipe, but is enough below the tees so that they can turn.

Control is by a rope or cable stretched from the ring, past the vertical drainpipe to the shore.

A pull on this line, by hand or machine, should raise the ring pipe and turn the drainpipe down.

The drainpipe can be raised by pulling the line from the opposite bank.

With some risk of twisting the end off instead of turning it, the masonry block may be omitted

and the outer tee replaced by a street ell welded to the inner tee.

The threads should be treated with waterproof grease or plumber’s dope, and wrought iron fit-

tings should be used if possible.

Metal pipe is expensive in large sizes, and 6-inch is about the minimum for a pond drain, except

for use in dry seasons only. Considerable expense may be saved by using concrete or tile pipe under

the dam, connecting it near the end with metal pipe to the valve or other drain arrangement.

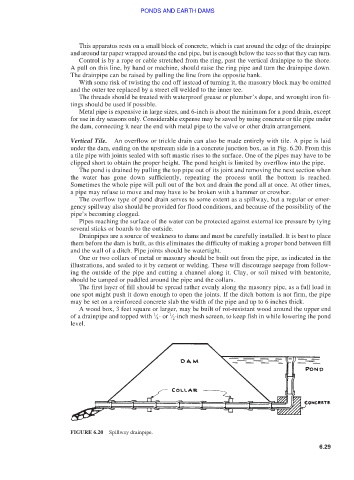

Vertical Tile. An overflow or trickle drain can also be made entirely with tile. A pipe is laid

under the dam, ending on the upstream side in a concrete junction box, as in Fig. 6.20. From this

a tile pipe with joints sealed with soft mastic rises to the surface. One of the pipes may have to be

clipped short to obtain the proper height. The pond height is limited by overflow into the pipe.

The pond is drained by pulling the top pipe out of its joint and removing the next section when

the water has gone down sufficiently, repeating the process until the bottom is reached.

Sometimes the whole pipe will pull out of the box and drain the pond all at once. At other times,

a pipe may refuse to move and may have to be broken with a hammer or crowbar.

The overflow type of pond drain serves to some extent as a spillway, but a regular or emer-

gency spillway also should be provided for flood conditions, and because of the possibility of the

pipe’s becoming clogged.

Pipes reaching the surface of the water can be protected against external ice pressure by tying

several sticks or boards to the outside.

Drainpipes are a source of weakness to dams and must be carefully installed. It is best to place

them before the dam is built, as this eliminates the difficulty of making a proper bond between fill

and the wall of a ditch. Pipe joints should be watertight.

One or two collars of metal or masonry should be built out from the pipe, as indicated in the

illustrations, and sealed to it by cement or welding. These will discourage seepage from follow-

ing the outside of the pipe and cutting a channel along it. Clay, or soil mixed with bentonite,

should be tamped or puddled around the pipe and the collars.

The first layer of fill should be spread rather evenly along the masonry pipe, as a full load in

one spot might push it down enough to open the joints. If the ditch bottom is not firm, the pipe

may be set on a reinforced concrete slab the width of the pipe and up to 6 inches thick.

A wood box, 3 feet square or larger, may be built of rot-resistant wood around the upper end

1

1

of a drainpipe and topped with ⁄ 4 - or ⁄ 2 -inch mesh screen, to keep fish in while lowering the pond

level.

FIGURE 6.20 Spillway drainpipe.

6.29