Page 418 - Moving the Earth_ The Workbook of Excavation

P. 418

BLASTING AND TUNNELING

9.18 THE WORK

Loading prills by compressed air may build up charges of static electricity in the borehole and

its vicinity. Such charges create danger of premature discharge of electric caps, and even possible

hazards with fuse caps. Minimum precautions are grounding of the pneumatic loader and use of

semiconducting hose. Caps should be of types least sensitive to stray currents.

This problem, and a number of important precautions, are discussed in a U.S. Bureau of Mines

Report, IC 8179, titled “Safety Recommendations for Sensitized Ammonium Nitrate Blasting Agents.”

Priming. Most AN-FO cannot be detonated dependably by blasting caps or regular Primacord.

Even when detonated, it may not maintain full speed of explosion, or even any explosion, for the

length of the hole.

It is therefore necessary to use primers or boosters that can be exploded by caps or Primacord,

and that will produce sufficient explosion to detonate the AN-FO at high velocity; and to use enough

of them in the hole that the explosion wave will not have enough space between them to weaken.

Such primers may be made of one or more sticks of gelatin dynamite of 60 percent or higher

strengths, or of special “cast” explosives. The cast boosters are somewhat more expensive than

dynamite, but are safer to handle and are more powerful.

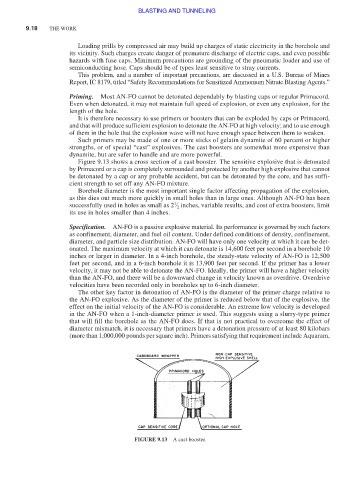

Figure 9.13 shows a cross section of a cast booster. The sensitive explosive that is detonated

by Primacord or a cap is completely surrounded and protected by another high explosive that cannot

be detonated by a cap or any probable accident, but can be detonated by the core, and has suffi-

cient strength to set off any AN-FO mixture.

Borehole diameter is the most important single factor affecting propagation of the explosion,

as this dies out much more quickly in small holes than in large ones. Although AN-FO has been

1

successfully used in holes as small as 2 ⁄ 2 inches, variable results, and cost of extra boosters, limit

its use in holes smaller than 4 inches.

Specification. AN-FO is a passive explosive material. Its performance is governed by such factors

as confinement, diameter, and fuel oil content. Under defined conditions of density, confinement,

diameter, and particle size distribution. AN-FO will have only one velocity at which it can be det-

onated. The maximum velocity at which it can detonate is 14,600 feet per second in a borehole 10

inches or larger in diameter. In a 4-inch borehole, the steady-state velocity of AN-FO is 12,500

feet per second, and in a 6-inch borehole it is 13,900 feet per second. If the primer has a lower

velocity, it may not be able to detonate the AN-FO. Ideally, the primer will have a higher velocity

than the AN-FO, and there will be a downward change in velocity known as overdrive. Overdrive

velocities have been recorded only in boreholes up to 6-inch diameter.

The other key factor in detonation of AN-FO is the diameter of the primer charge relative to

the AN-FO explosive. As the diameter of the primer is reduced below that of the explosive, the

effect on the initial velocity of the AN-FO is considerable. An extreme low velocity is developed

in the AN-FO when a 1-inch-diameter primer is used. This suggests using a slurry-type primer

that will fill the borehole as the AN-FO does. If that is not practical to overcome the effect of

diameter mismatch, it is necessary that primers have a detonation pressure of at least 80 kilobars

(more than 1,000,000 pounds per square inch). Primers satisfying that requirement include Aquaram,

FIGURE 9.13 A cast booster.