Page 430 - Moving the Earth_ The Workbook of Excavation

P. 430

BLASTING AND TUNNELING

9.30 THE WORK

Cartridges smaller than the hole are slit up the sides in two to four places, so they will spread

when tamped. Slitting is better than unwrapping, because of reduced danger from spilled powder

or of headache from skin contact, and the wrapper ends prevent powder from sticking to the tamper.

Some cartridged explosives have special perforated wrappers that do not need slitting, as they

tear and unwind under heavy end pressure.

Tamping. Tamping is a process of compacting explosives in boreholes by comparatively light

blows, and/or pressure, of a stick or weight. This tool must not have exposed metal of any kind.

For best compaction, tamp each cartridge or layer separately with a firm, pressing stroke.

Sharp blows are less effective, and should be avoided.

A tamping stick should be of round wood, with slightly smaller size than the smallest part of

the hole, with a straight cut across the working end. If the hole is too deep for the use of a single

tamping stick, several sticks should be drilled lengthwise and strung together with a cord. When

the cord is slack, the stick will fold and can easily be fed into the hole. If any stick is held, and the

cord tightened above it, the joints below the pull will be made rigid.

If the lower end of the stick wears to a taper, it should be cut back. The taper may punch holes

in the tops of cartridges that would not be filled by pressure on the next one placed, it may grind

some of the powder against the sides, and it may stick in cartridges and pick them up.

Large blast holes made by rotaries are usually tamped with a block on the end of a rope. The block

should be of hardwood to resist abrasion, be slightly smaller than the bore of the hole, and have a flat end.

If weight is needed for heavy tamping, or working in wet holes that would float wood, the block

may be drilled and weighted with lead or other heavy metal plugs, which should be covered with wood.

This type of block is not adapted to ramming down cartridges which have stuck in the hole

above the bottom, as it may cause excessive side friction. A special block with a chisel-point stake

that will break up the stuck cartridges is better.

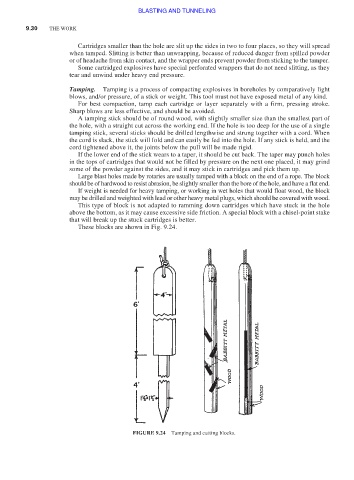

These blocks are shown in Fig. 9.24.

FIGURE 9.24 Tamping and cutting blocks.