Page 449 - Moving the Earth_ The Workbook of Excavation

P. 449

BLASTING AND TUNNELING

BLASTING AND TUNNELING 9.49

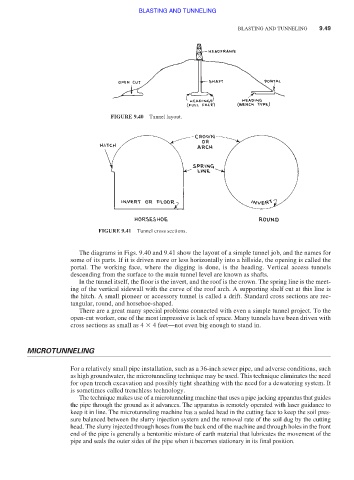

FIGURE 9.40 Tunnel layout.

FIGURE 9.41 Tunnel cross sections.

The diagrams in Figs. 9.40 and 9.41 show the layout of a simple tunnel job, and the names for

some of its parts. If it is driven more or less horizontally into a hillside, the opening is called the

portal. The working face, where the digging is done, is the heading. Vertical access tunnels

descending from the surface to the main tunnel level are known as shafts.

In the tunnel itself, the floor is the invert, and the roof is the crown. The spring line is the meet-

ing of the vertical sidewall with the curve of the roof arch. A supporting shelf cut at this line is

the hitch. A small pioneer or accessory tunnel is called a drift. Standard cross sections are rec-

tangular, round, and horsehoe-shaped.

There are a great many special problems connected with even a simple tunnel project. To the

open-cut worker, one of the most impressive is lack of space. Many tunnels have been driven with

cross sections as small as 4 4 feet—not even big enough to stand in.

MICROTUNNELING

For a relatively small pipe installation, such as a 36-inch sewer pipe, and adverse conditions, such

as high groundwater, the microtunneling technique may be used. This technique eliminates the need

for open trench excavation and possibly tight sheathing with the need for a dewatering system. It

is sometimes called trenchless technology.

The technique makes use of a microtunneling machine that uses a pipe jacking apparatus that guides

the pipe through the ground as it advances. The apparatus is remotely operated with laser guidance to

keep it in line. The microtunneling machine has a sealed head in the cutting face to keep the soil pres-

sure balanced between the slurry injection system and the removal rate of the soil dug by the cutting

head. The slurry injected through hoses from the back end of the machine and through holes in the front

end of the pipe is generally a bentonitic mixture of earth material that lubricates the movement of the

pipe and seals the outer sides of the pipe when it becomes stationary in its final position.