Page 518 - Moving the Earth_ The Workbook of Excavation

P. 518

PIT OPERATION

10.24 THE WORK

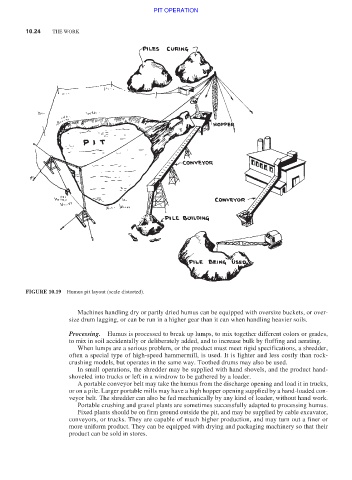

FIGURE 10.19 Humus pit layout (scale distorted).

Machines handling dry or partly dried humus can be equipped with oversize buckets, or over-

size drum lagging, or can be run in a higher gear than it can when handling heavier soils.

Processing. Humus is processed to break up lumps, to mix together different colors or grades,

to mix in soil accidentally or deliberately added, and to increase bulk by fluffing and aerating.

When lumps are a serious problem, or the product must meet rigid specifications, a shredder,

often a special type of high-speed hammermill, is used. It is lighter and less costly than rock-

crushing models, but operates in the same way. Toothed drums may also be used.

In small operations, the shredder may be supplied with hand shovels, and the product hand-

shoveled into trucks or left in a windrow to be gathered by a loader.

A portable conveyor belt may take the humus from the discharge opening and load it in trucks,

or on a pile. Larger portable mills may have a high hopper opening supplied by a hand-loaded con-

veyor belt. The shredder can also be fed mechanically by any kind of loader, without hand work.

Portable crushing and gravel plants are sometimes successfully adapted to processing humus.

Fixed plants should be on firm ground outside the pit, and may be supplied by cable excavator,

conveyors, or trucks. They are capable of much higher production, and may turn out a finer or

more uniform product. They can be equipped with drying and packaging machinery so that their

product can be sold in stores.