Page 190 - Materials Chemistry, Second Edition

P. 190

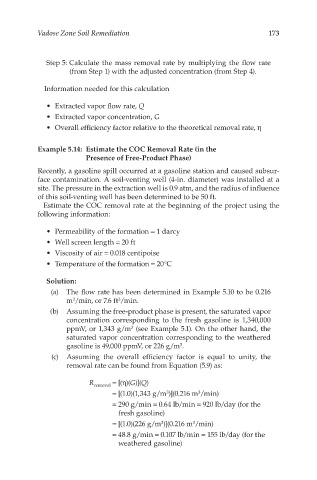

Vadose Zone Soil Remediation 173

Step 5: Calculate the mass removal rate by multiplying the flow rate

(from Step 1) with the adjusted concentration (from Step 4).

Information needed for this calculation

• Extracted vapor flow rate, Q

• Extracted vapor concentration, G

• Overall efficiency factor relative to the theoretical removal rate, η

Example 5.14: Estimate the COC Removal Rate (in the

Presence of Free-Product Phase)

Recently, a gasoline spill occurred at a gasoline station and caused subsur-

face contamination. A soil-venting well (4-in. diameter) was installed at a

site. The pressure in the extraction well is 0.9 atm, and the radius of influence

of this soil-venting well has been determined to be 50 ft.

Estimate the COC removal rate at the beginning of the project using the

following information:

• Permeability of the formation = 1 darcy

• Well screen length = 20 ft

• Viscosity of air = 0.018 centipoise

• Temperature of the formation = 20°C

Solution:

(a) The flow rate has been determined in Example 5.10 to be 0.216

m /min, or 7.6 ft /min.

3

3

(b) Assuming the free-product phase is present, the saturated vapor

concentration corresponding to the fresh gasoline is 1,340,000

ppmV, or 1,343 g/m (see Example 5.1). On the other hand, the

3

saturated vapor concentration corresponding to the weathered

gasoline is 49,000 ppmV, or 226 g/m .

3

(c) Assuming the overall efficiency factor is equal to unity, the

removal rate can be found from Equation (5.9) as:

R removal = [(η)(G)](Q)

= [(1.0)(1,343 g/m )](0.216 m /min)

3

3

= 290 g/min = 0.64 lb/min = 920 lb/day (for the

fresh gasoline)

= [(1.0)(226 g/m )](0.216 m /min)

3

3

= 48.8 g/min = 0.107 lb/min = 155 lb/day (for the

weathered gasoline)