Page 276 -

P. 276

OXIDATION AND DISINFECTION 10.21

DR£S5~£ RELIEF VALVE

(R(LIEVES AT I0" TO ZO"

DIFJCEREN TJAL REGU~AI"ING

LEGEND

I--'~GAS

V~LAYd GAUGE 'Tr

~WATER

t/3 ° ro 40"

~SOLuT~O~

CHLORINE GAS

FEED,ER

n----

STANDARO

v~CuUe

SOLUTION

~EGULATO~ L DISCHARGE

CH~CK UNIT

INaCCTOFt

GAS

~

REMOTE FROM

CONTROL MODULE

AuTO~AT~

• SWlTCHOVER

~VECTOR

i , CM~C~ UN,V •

war£R SUPPLY

i ~ I~:SEO r~ PAmSJ O~N RELIEF"

SUP~L~

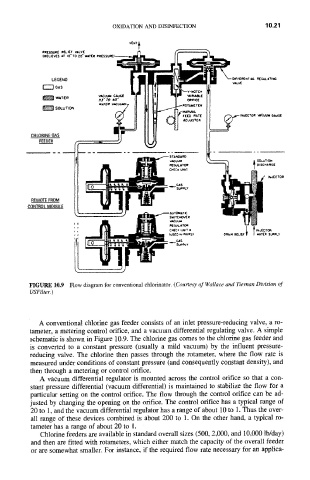

FIGURE 10.9 Flow diagram for conventional chlorinator. (Courtesy of Wallace and Tiernan Division of

USFilter.)

A conventional chlorine gas feeder consists of an inlet pressure-reducing valve, a ro-

tameter, a metering control orifice, and a vacuum differential regulating valve. A simple

schematic is shown in Figure 10.9. The chlorine gas comes to the chlorine gas feeder and

is converted to a constant pressure (usually a mild vacuum) by the influent pressure-

reducing valve. The chlorine then passes through the rotameter, where the flow rate is

measured under conditions of constant pressure (and consequently constant density), and

then through a metering or control orifice.

A vacuum differential regulator is mounted across the control orifice so that a con-

stant pressure differential (vacuum differential) is maintained to stabilize the flow for a

particular setting on the control orifice. The flow through the control orifice can be ad-

justed by changing the opening on the orifice. The control orifice has a typical range of

20 to 1, and the vacuum differential regulator has a range of about 10 to 1. Thus the over-

all range of these devices combined is about 200 to 1. On the other hand, a typical ro-

tameter has a range of about 20 to 1.

Chlorine feeders are available in standard overall sizes (500, 2,000, and 10,000 lb/day)

and then are fitted with rotameters, which either match the capacity of the overall feeder

or are somewhat smaller. For instance, if the required flow rate necessary for an applica-