Page 354 -

P. 354

ION EXCHANGE APPLICATIONS IN WATER TREATMENT ] 2.13

ences in relative affinities and concentrations. Those substances with high affinities can

continue to load to higher concentrations on the resins by displacing others previously ex-

changed but with lower relative affinities.

The gel-type strongly basic resins whose functional groups are based on either trimethyl-

amine (these are called type I) or dimethylethanolamine (these are called type II), have

the approximately same order of affinities for the common ions found in potable water

except for the hydroxide ion, which is not a factor here, and perchlorate. When operated

in the salt cycle, the regeneration efficiency is about the same for both types.

The general order of affinities for both types of strongly basic resins for the common

ions found in water at less than 500 ppm total dissolved electrolytes is

PO4 > SeO4 > SO4 > NO3 = AsO4 > SeO3 > CO3 ~ AsO3 > HCO3

Ion exchangers using strong base resins that are regenerated with NaC1 are commonly re-

ferred to as anion softeners because of the similarity of the equipment to the traditional

cation-based water softeners. When the pH of the resin is at or above 7, anion resins tend

to give off fishy odors. This is due to the (slow) decomposition of their functional groups,

which are amine-based. The alkanol amine group of the type II resin gives off less of-

fensive odors than the type I resins and is sometimes preferred over the type I resins in

potable water applications for this reason.

When a strong base resin is operated in the chloride cycle, it will exchange chlorides

for all the incoming anions. When all the exchangeable ions, in this case chlorides, have

been used up, the resin bed will contain only the ions that it removed from the raw wa-

ter. These ions will have distributed themselves in order of their relative affinities.

The bicarbonate ion is the least strongly held and is positioned nearest the exit end of

the vessel. If the vessel is operated as a dealkalizer, the service cycle would be ended at

this point and the vessel regenerated with a salt (NaC1) solution. However, if the vessel

is used for nitrate removal and there is no desire to remove bicarbonates, the service cy-

cle would continue. The nitrates and other ions would continue to be exchanged onto the

resin bed, and the bicarbonates would be driven off. The service cycle would end when

the nitrates on the resin were pushed down to the exit end of the vessel. Regardless of the

application, the vessel, resins, and regeneration equipment are identical. The operating ca-

pacity of course depends on the composition of the untreated water, the concentration of

the impurity being removed, and the specific goal of the treatment. The specific applica-

tions are discussed separately in the following sections.

Dealkalization

Dealkalization is the removal of bicarbonates, carbonates, and hydroxides. In potable wa-

ters the hydroxides could be controlled simply by injection of acid. This leaves bicar-

bonates and carbonates which are not amenable to acid injection because of the increased

corrosivity at lower pH. Strongly basic anion exchange resins operated in the chloride cy-

cle can remove bicarbonates and carbonates in exchange for chlorides. This also elimi-

nates "temporary hardness," which is an effective way of minimizing scale buildup in wa-

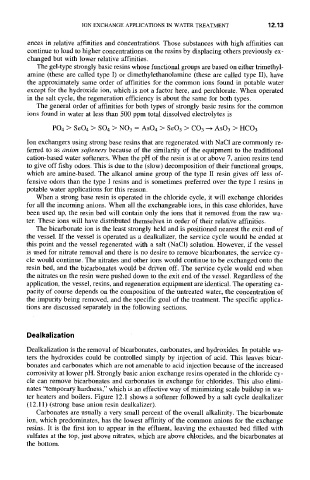

ter heaters and boilers. Figure 12.1 shows a softener followed by a salt cycle dealkalizer

(12.11) (strong base anion resin dealkalizer).

Carbonates are usually a very small percent of the overall alkalinity. The bicarbonate

ion, which predominates, has the lowest affinity of the common anions for the exchange

resins. It is the first ion to appear in the effluent, leaving the exhausted bed filled with

sulfates at the top, just above nitrates, which are above chlorides, and the bicarbonates at

the bottom.