Page 529 -

P. 529

15.34 CHAPTER FIFTEEN

Suction lines between supply tanks and pumps must be kept as short as possible, and

the entire system should be located close to the application point. Where possible, it is

important to avoid a layout that permits siphoning by simultaneous existence of positive

suction pressure and low or negative discharge pressure on the pump. Back pressure valves

installed on the discharge line prevent this condition and can help maintain the accuracy

of discharge on diaphragm metering pumps. Back pressure valves should not be used for

slurry applications.

Piping system design for use with oscillating or reciprocating pumps must be carefully

prepared to avoid cavitation in the pump chamber and vapor lock in the suction piping

from low suction pressures below the net positive suction head (NPSH) required. These

effects occur because of the inertia effect on the liquid column from the movement of the

piston or diaphragm as it changes direction on either end of the stroke.

The NPSH required must be established for the chemical being conveyed and then

compared with the available NPSH based on piping head losses calculated for both vis-

cosity head loss and acceleration head loss. The higher of these two head losses is used

to calculate available NPSH. Suction chambers located close to metering pumps can min-

imize head losses in suction piping due to pulsating flows. Discharge pressures based on

piping head losses must also be determined using the higher of these two types of head

loss.

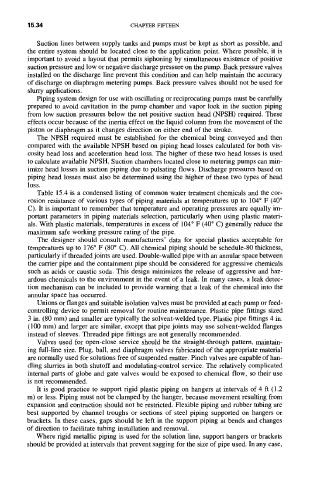

Table 15.4 is a condensed listing of common water treatment chemicals and the cor-

rosion resistance of various types of piping materials at temperatures up to 104 ° F (40 °

C). It is important to remember that temperature and operating pressures are equally im-

portant parameters in piping materials selection, particularly when using plastic materi-

als. With plastic materials, temperatures in excess of 104 ° F (40 ° C) generally reduce the

maximum safe working pressure rating of the pipe.

The designer should consult manufacturers' data for special plastics acceptable for

temperatures up to 176 ° F (80 ° C). All chemical piping should be schedule-80 thickness,

particularly if threaded joints are used. Double-walled pipe with an annular space between

the carrier pipe and the containment pipe should be considered for aggressive chemicals

such as acids or caustic soda. This design minimizes the release of aggressive and haz-

ardous chemicals to the environment in the event of a leak. In many cases, a leak detec-

tion mechanism can be included to provide warning that a leak of the chemical into the

annular space has occurred.

Unions or flanges and suitable isolation valves must be provided at each pump or feed-

controlling device to permit removal for routine maintenance. Plastic pipe fittings sized

3 in. (80 mm) and smaller are typically the solvent-welded type. Plastic pipe fittings 4 in.

(100 mm) and larger are similar, except that pipe joints may use solvent-welded flanges

instead of sleeves. Threaded pipe fittings are not generally recommended.

Valves used for open-close service should be the straight-through pattern, maintain-

ing full-line size. Plug, ball, and diaphragm valves fabricated of the appropriate material

are normally used for solutions free of suspended matter. Pinch valves are capable of han-

dling slurries in both shutoff and modulating-control service. The relatively complicated

internal parts of globe and gate valves would be exposed to chemical flow, so their use

is not recommended.

It is good practice to support rigid plastic piping on hangers at intervals of 4 ft (1.2

m) or less. Piping must not be clamped by the hanger, because movement resulting from

expansion and contraction should not be restricted. Flexible piping and rubber tubing are

best supported by channel troughs or sections of steel piping supported on hangers or

brackets. In these cases, gaps should be left in the support piping at bends and changes

of direction to facilitate tubing installation and removal.

Where rigid metallic piping is used for the solution line, support hangers or brackets

should be provided at intervals that prevent sagging for the size of pipe used. In any case,