Page 136 - A Comprehensive Guide to Solar Energy Systems

P. 136

Chapter 7 • Concentrating Solar Thermal Power 135

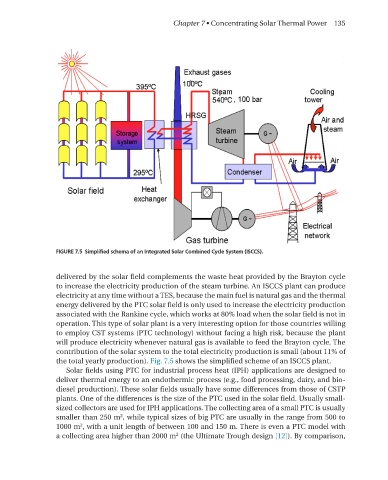

FIGURE 7.5 Simplified schema of an Integrated Solar Combined Cycle System (ISCCS).

delivered by the solar field complements the waste heat provided by the Brayton cycle

to increase the electricity production of the steam turbine. An ISCCS plant can produce

electricity at any time without a TES, because the main fuel is natural gas and the thermal

energy delivered by the PTC solar field is only used to increase the electricity production

associated with the Rankine cycle, which works at 80% load when the solar field is not in

operation. This type of solar plant is a very interesting option for those countries willing

to employ CST systems (PTC technology) without facing a high risk, because the plant

will produce electricity whenever natural gas is available to feed the Brayton cycle. The

contribution of the solar system to the total electricity production is small (about 11% of

the total yearly production). Fig. 7.5 shows the simplified scheme of an ISCCS plant.

Solar fields using PTC for industrial process heat (IPH) applications are designed to

deliver thermal energy to an endothermic process (e.g., food processing, dairy, and bio-

diesel production). These solar fields usually have some differences from those of CSTP

plants. One of the differences is the size of the PTC used in the solar field. usually small-

sized collectors are used for IPH applications. The collecting area of a small PTC is usually

smaller than 250 m , while typical sizes of big PTC are usually in the range from 500 to

2

2

1000 m , with a unit length of between 100 and 150 m. There is even a PTC model with

2

a collecting area higher than 2000 m (the ultimate Trough design [12]). By comparison,