Page 59 - Quick Guide to Welding and Weld Inspection by S.E. Hughes, Clifford Matthews

P. 59

A Quick Guide to Welding and Weld Inspection

Heat treatment of steels

Metallic materials consist of a microstructure of small

crystals called grains. The grain size and composition help

determine the overall mechanical behaviour of the metal.

Heat treatment provides an efficient way to manipulate the

properties of the metal by controlling the formation of

structures, changing the metal properties or controlling the

rate of cooling within the microstructure. All heat treatments

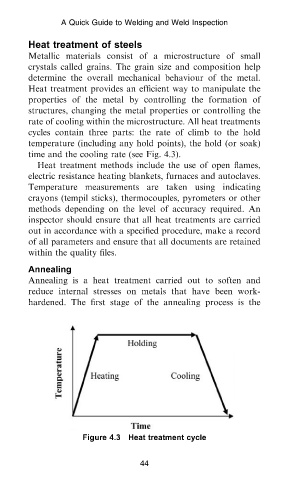

cycles contain three parts: the rate of climb to the hold

temperature (including any hold points), the hold (or soak)

time and the cooling rate (see Fig. 4.3).

Heat treatment methods include the use of open flames,

electric resistance heating blankets, furnaces and autoclaves.

Temperature measurements are taken using indicating

crayons (tempil sticks), thermocouples, pyrometers or other

methods depending on the level of accuracy required. An

inspector should ensure that all heat treatments are carried

out in accordance with a specified procedure, make a record

of all parameters and ensure that all documents are retained

within the quality files.

Annealing

Annealing is a heat treatment carried out to soften and

reduce internal stresses on metals that have been work-

hardened. The first stage of the annealing process is the

Figure 4.3 Heat treatment cycle

44

Woodhead Publishing Ltd – A Quick Guide to Welding and Weld Inspection

Data Standards Ltd, Frome, Somerset – 17/9/200904QG Welding chap4.3d Page 44 of 48