Page 6 - Quick Guide to Welding and Weld Inspection by S.E. Hughes, Clifford Matthews

P. 6

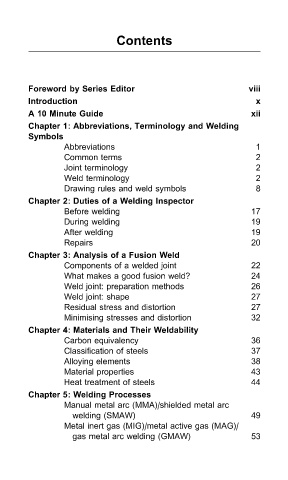

Contents

Foreword by Series Editor viii

Introduction x

A 10 Minute Guide xii

Chapter 1: Abbreviations, Terminology and Welding

Symbols

Abbreviations 1

Common terms 2

Joint terminology 2

Weld terminology 2

Drawing rules and weld symbols 8

Chapter 2: Duties of a Welding Inspector

Before welding 17

During welding 19

After welding 19

Repairs 20

Chapter 3: Analysis of a Fusion Weld

Components of a welded joint 22

What makes a good fusion weld? 24

Weld joint: preparation methods 26

Weld joint: shape 27

Residual stress and distortion 27

Minimising stresses and distortion 32

Chapter 4: Materials and Their Weldability

Carbon equivalency 36

Classification of steels 37

Alloying elements 38

Material properties 43

Heat treatment of steels 44

Chapter 5: Welding Processes

Manual metal arc (MMA)/shielded metal arc

welding (SMAW) 49

Metal inert gas (MIG)/metal active gas (MAG)/

gas metal arc welding (GMAW) 53

Woodhead Publishing Ltd – A Quick Guide to Welding and Weld Inspection

Data Standards Ltd, Frome, Somerset – 17/9/200900QG Welding Prelims.3d Page 5 of 14