Page 77 - Quick Guide to Welding and Weld Inspection by S.E. Hughes, Clifford Matthews

P. 77

A Quick Guide to Welding and Weld Inspection

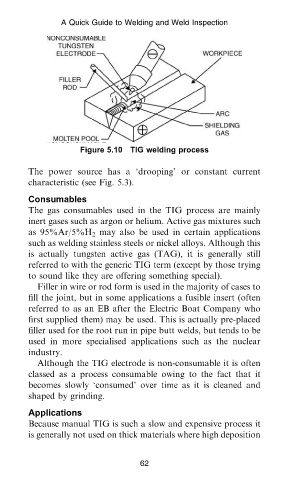

Figure 5.10 TIG welding process

The power source has a ‘drooping’ or constant current

characteristic (see Fig. 5.3).

Consumables

The gas consumables used in the TIG process are mainly

inert gases such as argon or helium. Active gas mixtures such

as 95%Ar/5%H 2 may also be used in certain applications

such as welding stainless steels or nickel alloys. Although this

is actually tungsten active gas (TAG), it is generally still

referred to with the generic TIG term (except by those trying

to sound like they are offering something special).

Filler in wire or rod form is used in the majority of cases to

fill the joint, but in some applications a fusible insert (often

referred to as an EB after the Electric Boat Company who

first supplied them) may be used. This is actually pre-placed

filler used for the root run in pipe butt welds, but tends to be

used in more specialised applications such as the nuclear

industry.

Although the TIG electrode is non-consumable it is often

classed as a process consumable owing to the fact that it

becomes slowly ‘consumed’ over time as it is cleaned and

shaped by grinding.

Applications

Because manual TIG is such a slow and expensive process it

is generally not used on thick materials where high deposition

62

Woodhead Publishing Ltd – A Quick Guide to Welding and Weld Inspection

Data Standards Ltd, Frome, Somerset – 17/9/200905QG Welding chap5.3d Page 62 of 66