Page 48 - Adsorbents fundamentals and applications

P. 48

TEMPERATURE SWING ADSORPTION AND PRESSURE SWING ADSORPTION 33

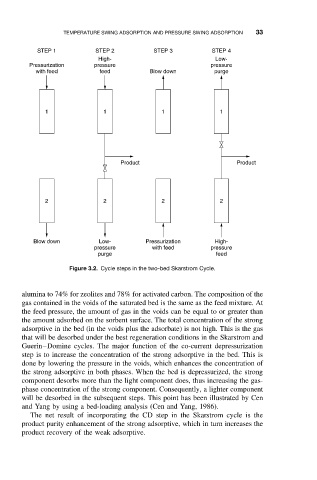

STEP 1 STEP 2 STEP 3 STEP 4

High- Low-

Pressurization pressure pressure

with feed feed Blow down purge

1 1 1 1

Product Product

2 2 2 2

Blow down Low- Pressurization High-

pressure with feed pressure

purge feed

Figure 3.2. Cycle steps in the two-bed Skarstrom Cycle.

alumina to 74% for zeolites and 78% for activated carbon. The composition of the

gas contained in the voids of the saturated bed is the same as the feed mixture. At

the feed pressure, the amount of gas in the voids can be equal to or greater than

the amount adsorbed on the sorbent surface. The total concentration of the strong

adsorptive in the bed (in the voids plus the adsorbate) is not high. This is the gas

that will be desorbed under the best regeneration conditions in the Skarstrom and

Guerin–Domine cycles. The major function of the co-current depressurization

step is to increase the concentration of the strong adsorptive in the bed. This is

done by lowering the pressure in the voids, which enhances the concentration of

the strong adsorptive in both phases. When the bed is depressurized, the strong

component desorbs more than the light component does, thus increasing the gas-

phase concentration of the strong component. Consequently, a lighter component

will be desorbed in the subsequent steps. This point has been illustrated by Cen

and Yang by using a bed-loading analysis (Cen and Yang, 1986).

The net result of incorporating the CD step in the Skarstrom cycle is the

product purity enhancement of the strong adsorptive, which in turn increases the

product recovery of the weak adsorptive.