Page 21 - Adsorptionbypowders & poroussolids muyace

P. 21

CHAPTER 1 INTRODUCTION 7

--

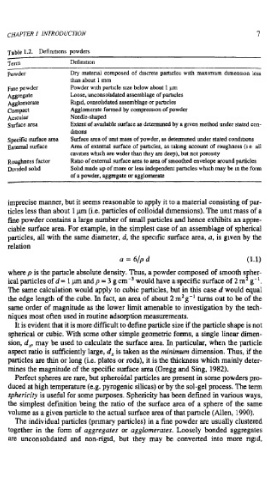

Table 1.2. Defirut~ons powders

Tern Defin~tlon

powder Dry matenal composed of discrete parhcles with maxlmum dunens~on less

than about 1 mm

Fme powder Powder with particle slze below about 1 pm

Aggregate Loose, unconsohdated assemblage of particles

Agglomerate bgld, consol~dated assemblage or parhcles

compact Agglomerate formed by compression of powder

Ac~cul~ Needle-shaped

surface area Extent of avalable surface as detemed by a glven method under stated con-

dtlons

Specific surface area Surface area of umt mass of powder, as determmed under stated condibons

External surface Area of external surface of particles, as takmg account of roughness (1 e all

cavrtles whlch are wlder than they are deep). but not porosity

Roughness factor Ratlo of external surface area to area of smoothed envelope around particles

Divided sohd Solid made up of more or less independent pamcles wh~ch may be m the form

of a powder, aggregate or agglomerate

imprecise manner, but it seems reasonable to apply it to a material consisting of par-

ticles less than about 1 p.rn (i.e. particles of colloidal dimensions). The unit mass of a

fine powder contains a large number of small particles and hence exhibits an appre-

ciable surface area. For example, in the simplest case of an assemblage of spherical

particles, all with the same diameter, d, the specific surface area, a, is given by the

relation

where p is the particle absolute density. Thus, a powder composed of smooth spher-

ical particles of d = 1 p.rn and p = 3 g cm-3 would have a specific surface of 2 mZ g-'.

The same calculation would apply to cubic particles, but in this case d would equal

the edge length of the cube. In fact, an area of about 2 mZg-' turns out to be of the

same order of magnitude as the lower limit amenable to investigation by the tech-

niques most often used in routine adsorption measurements.

It is evident that it is more difficult to &fine particle size if the particle shape is not

spherical or cubic. With some other simple geometric forms, a single linear dimen-

sion, d, may be used to calculate the surface area. In particular, when the particle

aspect ratio is sufficiently large, d, is taken as the minimum dimension. Thus, if the

particles are thin or long (i.e. plates or rods), it is the thickness which mainly deter-

mines the magnitude of the specific surface area (Gregg and Sing, 1982).

Perfect spheres are rare, but spheroidal particles are present in some powders pro-

duced at high temperature (e.g. pyrogenic silicas) or by the sol-gel process. The term

sphericity is useful for some purposes. Sphericity has been defined in various ways,

the simplest definition being the ratio of the surface area of a sphere of the same

volume as a given particle to the actual surface area of that particle (Allen, 1990).

The individual particles (pnrnary particles) in a fine powder are usually clustered

together in the form of aggregates or agglomerates. Loosely bonded aggregates

are unconsolidated and non-rigid, but they may be converted into more ng~d,