Page 207 - Adsorption Technology & Design, Elsevier (1998)

P. 207

Selected adsorption processes 193

been adopted for many drying plants especially when the air or gas pressure

supply is available at a moderately high pressure. In a typical two-bed

adsorption unit, each bed is subjected to pressurization and adsorption steps

followed by countercurrent blowdown and purge. Cycle times vary from I to

10 minutes - very much shorter than the corresponding thermal swing

process (compare with Section 7.4.1). Short cycle times help to conserve the

heat of adsorption and experimental evidence for this indicates that

temperatures in each bed vary by less than 10~ (Chihara and Suzuki 1983).

To obtain a high purity product with a low dewpoint the purge to feed flow

ratios should be between 1.1 and 2.0 and the ratio of high pressure (when

adsorbing) to low pressure (during regeneration) should be greater than the

reciprocal of the mole fraction of the product contained in the feed.

7.3.2 Hydrogen purification (Stewart and Heck 1969, Cassidy and

Holmes 1984)

Pressure swing adsorption units are used extensively for the purification of

hydrogen streams containing small amounts of low molecular weight

hydrocarbons. For most adsorbents, hydrogen is hardly adsorbed. Thus the

consequence is that ultra-high purity hydrogen may be recovered using

almost any adsorbent. Losses from blowdown and purge, although rela-

tively large, do not militate against a PSA process as recoveries of hydrogen

over 85% are possible and the feed gases wasted during blowdown and

purge steps are of little economic value.

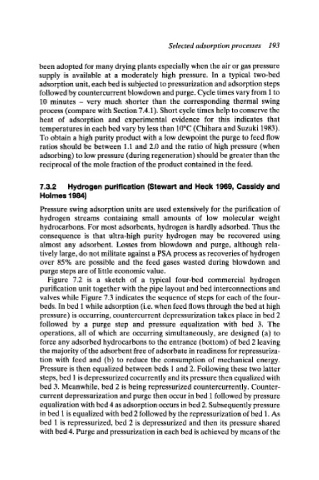

Figure 7.2 is a sketch of a typical four-bed commercial hydrogen

purification unit together with the pipe layout and bed interconnections and

valves while Figure 7.3 indicates the sequence of steps for each of the four-

beds. In bed I while adsorption (i.e. when feed flows through the bed at high

pressure) is occurring, countercurrent depressurization takes place in bed 2

followed by a purge step and pressure equalization with bed 3. The

operations, all of which are occurring simultaneously, are designed (a) to

force any adsorbed hydrocarbons to the entrance (bottom) of bed 2 leaving

the majority of the adsorbent free of adsorbate in readiness for repressuriza-

tion with feed and (b) to reduce the consumption of mechanical energy.

Pressure is then equalized between beds I and 2. Following these two latter

steps, bed I is depressurized cocurrently and its pressure then equalized with

bed 3. Meanwhile, bed 2 is being repressurized countercurrently. Counter-

current depressurization and purge then occur in bed I followed by pressure

equalization with bed 4 as adsorption occurs in bed 2. Subsequently pressure

in bed 1 is equalized with bed 2 followed by the repressurization of bed 1. As

bed 1 is repressurized, bed 2 is depressurized and then its pressure shared

with bed 4. Purge and pressurization in each bed is achieved by means of the