Page 258 - Adsorption Technology & Design, Elsevier (1998)

P. 258

Selected adsorption processes 233

where t is the time allowed for adsorption in the cycle (equal to desorption)

and k is the mass transfer coefficient for adsorption and desorption. Figure

7.21 illustrates how this function behaves with increasing value of t for

different values of k. It is apparent that, on the one hand, for an adsorption

without mass transfer limitation (k = ~) the net rate of adsorption increases

to infinity as t approaches zero. On the other hand, there is a limiting value of

k/4 as t approaches zero for finite values of k. Furthermore, when t

approaches zero the cycle inefficiency, 11(= 2tR/q*) also becomes zero.

The conclusion to be drawn from this argument is that rapid cycling between

the adsorption pressure pA and the desorption pressure pD (<Pg) leads to a

greater net rate of adsorption for a given adsorption capacity and better

cycle efficiency. Although a simple model was used to demonstrate this the

conclusion is valid for more realistic models of cycles. This has been shown

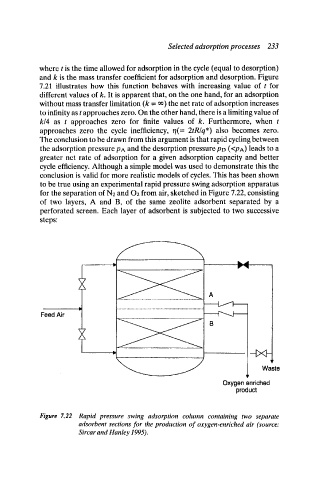

to be true using an experimental rapid pressure swing adsorption apparatus

for the separation of N2 and O2 from air, sketched in Figure 7.22, consisting

of two layers, A and B, of the same zeolite adsorbent separated by a

perforated screen. Each layer of adsorbent is subjected to two successive

steps:

A

I

Feed Air

8

1

Waste

Oxygen enriched

product

Figure 7.22 Rapid pressure swing adsorption column containing two separate

adsorbent sections for the production of oxygen-enriched air (source:

Sircar and Hanley 1995).