Page 164 - Advanced Gas Turbine Cycles

P. 164

Chapter 8. Novel gas turbine cycles 133

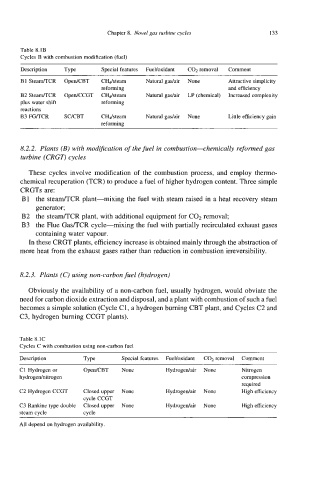

Table 8.1B

Cycles B with combustion modification (fuel)

Description Type Special features FueVoxidant C@ removal Comment

BI Steam/TCR OpedCBT CH.,/steam Naturalgadair None Attractive simplicity

reforming and efficiency

B2 StedCR OpedCCGT CH.,/steam Natural gadair LP (chemical) Increased complexity

plus water shift reforming

reactions

B3FGRCR SUCBT CH.,/steam Natural gadair None Little efficiency gain

reforming

8.2.2. Plants (B) with modifcation of the fuel in combustion-chemically reformed gas

turbine (CRGT) cycles

These cycles involve modification of the combustion process, and employ thermo-

chemical recuperation (TCR) to produce a fuel of higher hydrogen content. Three simple

CRGTs are:

B1 the steam/TCR plant-mixing the fuel with steam raised in a heat recovery steam

generator;

B2 the steam/TCR plant, with additional equipment for C02 removal;

B3 the Flue GasmCR cycle-mixing the fuel with partially recirculated exhaust gases

containing water vapour.

In these CRGT plants, efficiency increase is obtained mainly through the abstraction of

more heat from the exhaust gases rather than reduction in combustion irreversibility.

8.2.3. Plants (C) using non-carbon fuel (hydrogen)

Obviously the availability of a non-carbon fuel, usually hydrogen, would obviate the

need for carbon dioxide extraction and disposal, and a plant with combustion of such a fuel

becomes a simple solution (Cycle C1, a hydrogen burning CBT plant, and Cycles C2 and

C3, hydrogen burning CCGT plants).

Table 8. IC

Cycles C with combustion using non-carbon fuel

Description Type Special features FueVoxidant CO2 removal Comment

C1 Hydrogen or OpedCBT None Hydrogedair None Nitrogen

hydrogednitrogen compression

required

C2 Hydrogen CCGT Closed upper None Hydrogedair None High efficiency

cycle CCGT

C3 Rankine type double Closed upper None Hydrogedair None High efficiency

steam cvcle cvcle

All depend on hydrogen availability.