Page 74 - Advanced Mine Ventilation

P. 74

Estimation of Ventilation Air Quantity 57

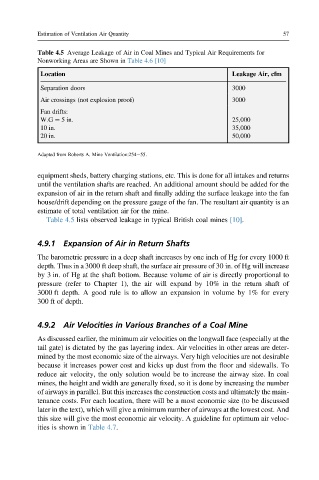

Table 4.5 Average Leakage of Air in Coal Mines and Typical Air Requirements for

Nonworking Areas are Shown in Table 4.6 [10]

Location Leakage Air, cfm

Separation doors 3000

Air crossings (not explosion proof) 3000

Fan drifts:

W.G ¼ 5 in. 25,000

10 in. 35,000

20 in. 50,000

Adapted from Roberts A. Mine Ventilation:254e55.

equipment sheds, battery charging stations, etc. This is done for all intakes and returns

until the ventilation shafts are reached. An additional amount should be added for the

expansion of air in the return shaft and finally adding the surface leakage into the fan

house/drift depending on the pressure gauge of the fan. The resultant air quantity is an

estimate of total ventilation air for the mine.

Table 4.5 lists observed leakage in typical British coal mines [10].

4.9.1 Expansion of Air in Return Shafts

The barometric pressure in a deep shaft increases by one inch of Hg for every 1000 ft

depth. Thus in a 3000 ft deep shaft, the surface air pressure of 30 in. of Hg will increase

by 3 in. of Hg at the shaft bottom. Because volume of air is directly proportional to

pressure (refer to Chapter 1), the air will expand by 10% in the return shaft of

3000 ft depth. A good rule is to allow an expansion in volume by 1% for every

300 ft of depth.

4.9.2 Air Velocities in Various Branches of a Coal Mine

As discussed earlier, the minimum air velocities on the longwall face (especially at the

tail gate) is dictated by the gas layering index. Air velocities in other areas are deter-

mined by the most economic size of the airways. Very high velocities are not desirable

because it increases power cost and kicks up dust from the floor and sidewalls. To

reduce air velocity, the only solution would be to increase the airway size. In coal

mines, the height and width are generally fixed, so it is done by increasing the number

of airways in parallel. But this increases the construction costs and ultimately the main-

tenance costs. For each location, there will be a most economic size (to be discussed

later in the text), which will give a minimum number of airways at the lowest cost. And

this size will give the most economic air velocity. A guideline for optimum air veloc-

ities is shown in Table 4.7.