Page 308 - Advanced Mine Ventilation

P. 308

Floor Gas Emissions and Gas Outbursts 285

reservoir pressures are measured. If the gas contents and pressures are high and the

coal seams are liable to outburst, they must be adequately degassed prior to mining.

Failure to degas the underlying coal seams have resulted in mine disasters in many Eu-

ropean and Australian coal mines owing to sudden outburst of gas and coal fines [3].

At present there are two techniques available to predrain these coal seams:

1. Hydrofracturing of underlying coal seams by a vertical well and

2. Horizontal boreholes drilled from surface to intersect all underlying coal seams in the gas

emission space, with or without hydrofracturing.

17.1.1.1 Hydrofracturing of Underlying Coal Seams

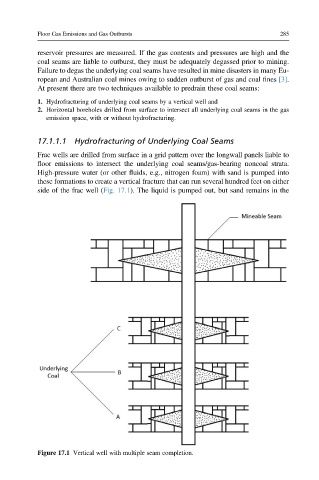

Frac wells are drilled from surface in a grid pattern over the longwall panels liable to

floor emissions to intersect the underlying coal seams/gas-bearing noncoal strata.

High-pressure water (or other fluids, e.g., nitrogen foam) with sand is pumped into

these formations to create a vertical fracture that can run several hundred feet on either

side of the frac well (Fig. 17.1). The liquid is pumped out, but sand remains in the

Figure 17.1 Vertical well with multiple seam completion.