Page 355 - Advanced Mine Ventilation

P. 355

332 Advanced Mine Ventilation

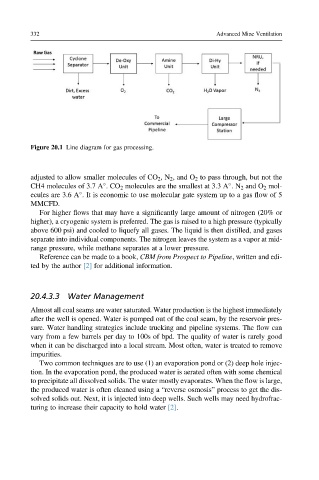

Figure 20.1 Line diagram for gas processing.

adjusted to allow smaller molecules of CO 2 ,N 2 , and O 2 to pass through, but not the

CH4 molecules of 3.7 A .CO 2 molecules are the smallest at 3.3 A .N 2 and O 2 mol-

ecules are 3.6 A . It is economic to use molecular gate system up to a gas flow of 5

MMCFD.

For higher flows that may have a significantly large amount of nitrogen (20% or

higher), a cryogenic system is preferred. The gas is raised to a high pressure (typically

above 600 psi) and cooled to liquefy all gases. The liquid is then distilled, and gases

separate into individual components. The nitrogen leaves the system as a vapor at mid-

range pressure, while methane separates at a lower pressure.

Reference can be made to a book, CBM from Prospect to Pipeline, written and edi-

ted by the author [2] for additional information.

20.4.3.3 Water Management

Almost all coal seams are water saturated. Water production is the highest immediately

after the well is opened. Water is pumped out of the coal seam, by the reservoir pres-

sure. Water handling strategies include trucking and pipeline systems. The flow can

vary from a few barrels per day to 100s of bpd. The quality of water is rarely good

when it can be discharged into a local stream. Most often, water is treated to remove

impurities.

Two common techniques are to use (1) an evaporation pond or (2) deep hole injec-

tion. In the evaporation pond, the produced water is aerated often with some chemical

to precipitate all dissolved solids. The water mostly evaporates. When the flow is large,

the produced water is often cleaned using a “reverse osmosis” process to get the dis-

solved solids out. Next, it is injected into deep wells. Such wells may need hydrofrac-

turing to increase their capacity to hold water [2].