Page 420 - Advanced Mine Ventilation

P. 420

Gas and Dust Explosions 389

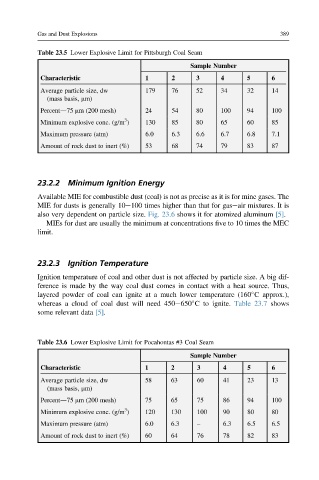

Table 23.5 Lower Explosive Limit for Pittsburgh Coal Seam

Sample Number

Characteristic 1 2 3 4 5 6

Average particle size, dw 179 76 52 34 32 14

(mass basis, mm)

Percentd75 mm (200 mesh) 24 54 80 100 94 100

3

Minimum explosive conc. (g/m ) 130 85 80 65 60 85

Maximum pressure (atm) 6.0 6.3 6.6 6.7 6.8 7.1

Amount of rock dust to inert (%) 53 68 74 79 83 87

23.2.2 Minimum Ignition Energy

Available MIE for combustible dust (coal) is not as precise as it is for mine gases. The

MIE for dusts is generally 10e100 times higher than that for gaseair mixtures. It is

also very dependent on particle size. Fig. 23.6 shows it for atomized aluminum [5].

MIEs for dust are usually the minimum at concentrations five to 10 times the MEC

limit.

23.2.3 Ignition Temperature

Ignition temperature of coal and other dust is not affected by particle size. A big dif-

ference is made by the way coal dust comes in contact with a heat source. Thus,

layered powder of coal can ignite at a much lower temperature (160 C approx.),

whereas a cloud of coal dust will need 450e650 C to ignite. Table 23.7 shows

some relevant data [5].

Table 23.6 Lower Explosive Limit for Pocahontas #3 Coal Seam

Sample Number

Characteristic 1 2 3 4 5 6

Average particle size, dw 58 63 60 41 23 13

(mass basis, mm)

Percentd75 mm (200 mesh) 75 65 75 86 94 100

3

Minimum explosive conc. (g/m ) 120 130 100 90 80 80

Maximum pressure (atm) 6.0 6.3 – 6.3 6.5 6.5

Amount of rock dust to inert (%) 60 64 76 78 82 83