Page 211 - Advances In Productive, Safe, and Responsible Coal Mining

P. 211

190 Advances in Productive, Safe, and Responsible Coal Mining

Fig. 10.5 Development of vertical gob wells in advance of mining [14].

content, and coal seam thickness. Overall, methane concentrations in gob gas vary

from 30% to 90%.

Predrainage systems can also be combined with postdrainage vertical gob wells as

an interesting commercial CMM capturing method. In this situation, CMM is first cap-

tured through a predrainage system in regions where methane flows exceed the capac-

ity of the mine ventilation system. When CMM emissions remain high even after face

advancement, a postdrainage system is then used to capture gases emitted in the gob

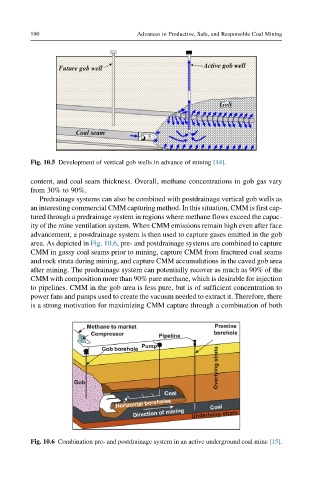

area. As depicted in Fig. 10.6, pre- and postdrainage systems are combined to capture

CMM in gassy coal seams prior to mining, capture CMM from fractured coal seams

and rock strata during mining, and capture CMM accumulations in the caved gob area

after mining. The predrainage system can potentially recover as much as 90% of the

CMM with composition more than 90% pure methane, which is desirable for injection

to pipelines. CMM in the gob area is less pure, but is of sufficient concentration to

power fans and pumps used to create the vacuum needed to extract it. Therefore, there

is a strong motivation for maximizing CMM capture through a combination of both

Fig. 10.6 Combination pre- and postdrainage system in an active underground coal mine [15].