Page 202 - Advances in Eco-Fuels for a Sustainable Environment

P. 202

166 Advances in Eco-Fuels for a Sustainable Environment

6.4.5 Solid to water content

Water and feedstock such as kitchen waste and food waste, should be added together

to generate slurry with the required stability. The production of biogas is ineffective if

the slurry is too thick or too dilute. The optimum solid concentration may range from

7% to 25%, depending on the type of feedstock used [21]. Crop residue weed plants

are added to achieve the optimum level because sewage waste contains shallow solid

content. Budiyono et al. [49] experimented the effect of total solid contents (2.6%,

4.6%, 6.2%, 7.4%, 9.2%, 12.3%, and 18.4%. of TS) on biogas yield using cattle

manure as a feedstock in a 400mL batch digester and found that 9.2% and 7.4% of

total solids achieved better performance on biogas production than total solid

percentages.

6.4.6 Carbon-to-nitrogen ratio

Improper carbon-nitrogen ratios may limit the efficiency of the anaerobic digestion.

The carbon dioxide production is higher and less pH ensued in the increase of carbon

content while a high value of nitrogen will increase formation of ammonia gas that

could advance the pH to the destruction of the microorganisms. When the carbon-

nitrogen ratio exceeds approximately 30, the biogas production diminishes. If the

C/N ratio is higher, methanogens consume rapid nitrogen and result in lower biogas

production. Accumulation of ammonia and pH values surpassing 8.5, which is toxic to

pathogens, occurs when the C/N ratio is lower. Feedstock with higher C/N ratio

co-digested with lower C/N ratio to maintain the optimum C/N ratio in the digestion

system. The effect of the C/N ratio of various feeds on biogas production showed that a

C/N ratio of 26:1 gives maximum biogas production compared to others, as shown in

Table 6.1 [50–52]. Moset et al. [53] examined seven different C/N ratios (6.62, 9.27,

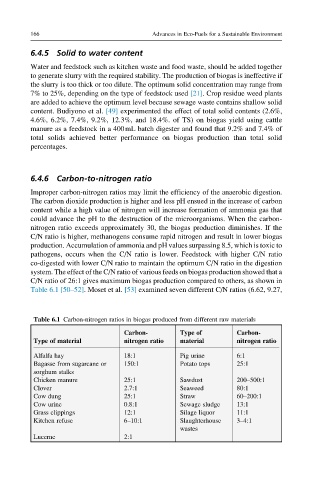

Table 6.1 Carbon-nitrogen ratios in biogas produced from different raw materials

Carbon- Type of Carbon-

Type of material nitrogen ratio material nitrogen ratio

Alfalfa hay 18:1 Pig urine 6:1

Bagasse from sugarcane or 150:1 Potato tops 25:1

sorghum stalks

Chicken manure 25:1 Sawdust 200–500:1

Clover 2.7:1 Seaweed 80:1

Cow dung 25:1 Straw 60–200:1

Cow urine 0.8:1 Sewage sludge 13:1

Grass clippings 12:1 Silage liquor 11:1

Kitchen refuse 6–10:1 Slaughterhouse 3–4:1

wastes

Lucerne 2:1