Page 266 - Advances in Eco-Fuels for a Sustainable Environment

P. 266

Prospects and technological advancement of cellulosic bioethanol ecofuel production 229

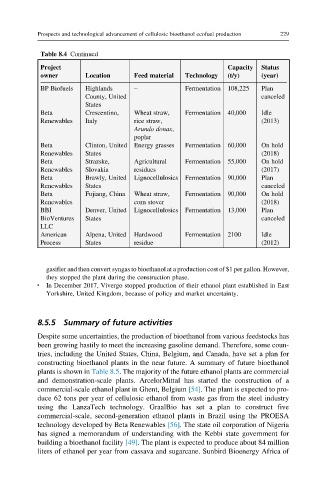

Table 8.4 Continued

Project Capacity Status

owner Location Feed material Technology (t/y) (year)

BP Biofuels Highlands – Fermentation 108,225 Plan

County, United canceled

States

Beta Crescentino, Wheat straw, Fermentation 40,000 Idle

Renewables Italy rice straw, (2013)

Arundo donax,

poplar

Beta Clinton, United Energy grasses Fermentation 60,000 On hold

Renewables States (2018)

Beta Strazske, Agricultural Fermentation 55,000 On hold

Renewables Slovakia residues (2017)

Beta Brawly, United Lignocellulosics Fermentation 90,000 Plan

Renewables States canceled

Beta Fujiang, China Wheat straw, Fermentation 90,000 On hold

Renewables corn stover (2018)

BBI Denver, United Lignocellulosics Fermentation 13,000 Plan

BioVentures States canceled

LLC

American Alpena, United Hardwood Fermentation 2100 Idle

Process States residue (2012)

gasifier and then convert syngas to bioethanol at a production cost of $1 per gallon. However,

they stopped the plant during the construction phase.

l In December 2017, Vivergo stopped production of their ethanol plant established in East

Yorkshire, United Kingdom, because of policy and market uncertainty.

8.5.5 Summary of future activities

Despite some uncertainties, the production of bioethanol from various feedstocks has

been growing hastily to meet the increasing gasoline demand. Therefore, some coun-

tries, including the United States, China, Belgium, and Canada, have set a plan for

constructing bioethanol plants in the near future. A summary of future bioethanol

plants is shown in Table 8.5. The majority of the future ethanol plants are commercial

and demonstration-scale plants. ArcelorMittal has started the construction of a

commercial-scale ethanol plant in Ghent, Belgium [54]. The plant is expected to pro-

duce 62 tons per year of cellulosic ethanol from waste gas from the steel industry

using the LanzaTech technology. GraalBio has set a plan to construct five

commercial-scale, second-generation ethanol plants in Brazil using the PROESA

technology developed by Beta Renewables [56]. The state oil corporation of Nigeria

has signed a memorandum of understanding with the Kebbi state government for

building a bioethanol facility [49]. The plant is expected to produce about 84 million

liters of ethanol per year from cassava and sugarcane. Sunbird Bioenergy Africa of