Page 173 - Advances in bioenergy the sustainability challenge

P. 173

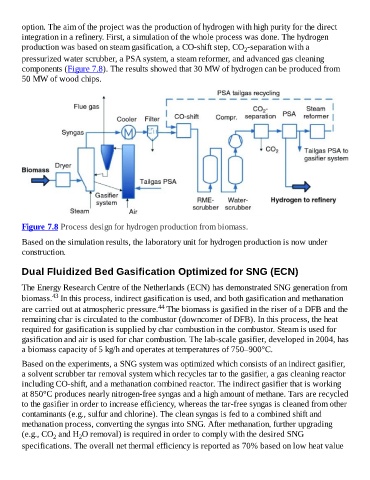

option. The aim of the project was the production of hydrogen with high purity for the direct

integration in a refinery. First, a simulation of the whole process was done. The hydrogen

production was based on steam gasification, a CO-shift step, CO -separation with a

2

pressurized water scrubber, a PSA system, a steam reformer, and advanced gas cleaning

components (Figure 7.8). The results showed that 30 MW of hydrogen can be produced from

50 MW of wood chips.

Figure 7.8 Process design for hydrogen production from biomass.

Based on the simulation results, the laboratory unit for hydrogen production is now under

construction.

Dual Fluidized Bed Gasification Optimized for SNG (ECN)

The Energy Research Centre of the Netherlands (ECN) has demonstrated SNG generation from

43

biomass. In this process, indirect gasification is used, and both gasification and methanation

44

are carried out at atmospheric pressure. The biomass is gasified in the riser of a DFB and the

remaining char is circulated to the combustor (downcomer of DFB). In this process, the heat

required for gasification is supplied by char combustion in the combustor. Steam is used for

gasification and air is used for char combustion. The lab-scale gasifier, developed in 2004, has

a biomass capacity of 5 kg/h and operates at temperatures of 750–900°C.

Based on the experiments, a SNG system was optimized which consists of an indirect gasifier,

a solvent scrubber tar removal system which recycles tar to the gasifier, a gas cleaning reactor

including CO-shift, and a methanation combined reactor. The indirect gasifier that is working

at 850°C produces nearly nitrogen-free syngas and a high amount of methane. Tars are recycled

to the gasifier in order to increase efficiency, whereas the tar-free syngas is cleaned from other

contaminants (e.g., sulfur and chlorine). The clean syngas is fed to a combined shift and

methanation process, converting the syngas into SNG. After methanation, further upgrading

(e.g., CO and H O removal) is required in order to comply with the desired SNG

2

2

specifications. The overall net thermal efficiency is reported as 70% based on low heat value