Page 110 - Air Pollution Control Engineering

P. 110

02_chap_wang.qxd 05/05/2004 12:40 pm Page 89

Fabric Filtration 89

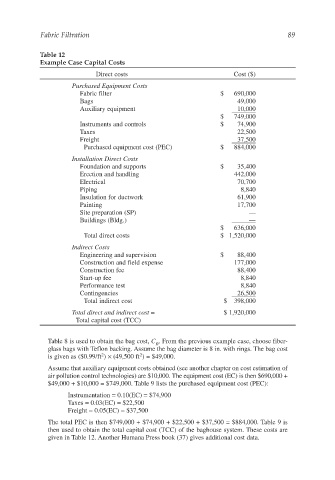

Table 12

Example Case Capital Costs

Direct costs Cost ($)

Purchased Equipment Costs

Fabric filter $ 690,000

Bags 49,000

Auxiliary equipment 10,000

$ 749,000

Instruments and controls $ 74,900

Taxes 22,500

Freight 37,500

Purchased equipment cost (PEC) $ 884,000

Installation Direct Costs

Foundation and supports $ 35,400

Erection and handling 442,000

Electrical 70,700

Piping 8,840

Insulation for ductwork 61,900

Painting 17,700

Site preparation (SP) —

Buildings (Bldg.) —

$ 636,000

Total direct costs $ 1,520,000

Indirect Costs

Engineering and supervision $ 88,400

Construction and field expense 177,000

Construction fee 88,400

Start-up fee 8,840

Performance test 8,840

Contingencies 26,500

Total indirect cost $ 398,000

Total direct and indirect cost = $ 1,920,000

Total capital cost (TCC)

Table 8 is used to obtain the bag cost, C . From the previous example case, choose fiber-

B

glass bags with Teflon backing. Assume the bag diameter is 8 in. with rings. The bag cost

2

2

is given as ($0.99/ft ) × (49,500 ft ) = $49,000.

Assume that auxiliary equipment costs obtained (see another chapter on cost estimation of

air pollution control technologies) are $10,000. The equipment cost (EC) is then $690,000 +

$49,000 + $10,000 = $749,000. Table 9 lists the purchased equipment cost (PEC):

Instrumentation = 0.10(EC) = $74,900

Taxes = 0.03(EC) = $22,500

Freight = 0.05(EC) = $37,500

The total PEC is then $749,000 + $74,900 + $22,500 + $37,500 = $884,000. Table 9 is

then used to obtain the total capital cost (TCC) of the baghouse system. These costs are

given in Table 12. Another Humana Press book (37) gives additional cost data.