Page 119 - Air Pollution Control Engineering

P. 119

03_chap_wang.qxd 05/05/2004 12:48 pm Page 98

98 José Renato Coury et al.

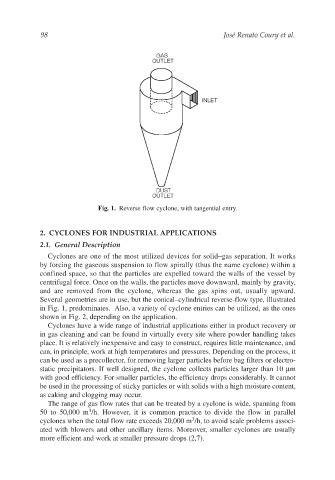

Fig. 1. Reverse flow cyclone, with tangential entry.

2. CYCLONES FOR INDUSTRIAL APPLICATIONS

2.1. General Description

Cyclones are one of the most utilized devices for solid–gas separation. It works

by forcing the gaseous suspension to flow spirally (thus the name cyclone) within a

confined space, so that the particles are expelled toward the walls of the vessel by

centrifugal force. Once on the walls, the particles move downward, mainly by gravity,

and are removed from the cyclone, whereas the gas spins out, usually upward.

Several geometries are in use, but the conical–cylindrical reverse-flow type, illustrated

in Fig. 1, predominates. Also, a variety of cyclone entries can be utilized, as the ones

shown in Fig. 2, depending on the application.

Cyclones have a wide range of industrial applications either in product recovery or

in gas cleaning and can be found in virtually every site where powder handling takes

place. It is relatively inexpensive and easy to construct, requires little maintenance, and

can, in principle, work at high temperatures and pressures. Depending on the process, it

can be used as a precollector, for removing larger particles before bag filters or electro-

static precipitators. If well designed, the cyclone collects particles larger than 10 µm

with good efficiency. For smaller particles, the efficiency drops considerably. It cannot

be used in the processing of sticky particles or with solids with a high moisture content,

as caking and clogging may occur.

The range of gas flow rates that can be treated by a cyclone is wide, spanning from

3

50 to 50,000 m /h. However, it is common practice to divide the flow in parallel

3

cyclones when the total flow rate exceeds 20,000 m /h, to avoid scale problems associ-

ated with blowers and other ancillary items. Moreover, smaller cyclones are usually

more efficient and work at smaller pressure drops (2,7).