Page 491 - Air Pollution Control Engineering

P. 491

12_ch_wang.qxd 05/05/2004 5:26 pm Page 463

Emerging Pollution Control Technologies 463

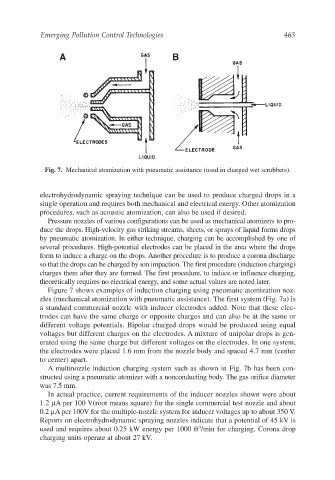

Fig. 7. Mechanical atomization with pneumatic assistance (used in charged wet scrubbers).

electrohydrodynamic spraying technique can be used to produce charged drops in a

single operation and requires both mechanical and electrical energy. Other atomization

procedures, such as acoustic atomization, can also be used if desired.

Pressure nozzles of various configurations can be used as mechanical atomizers to pro-

duce the drops. High-velocity gas striking streams, sheets, or sprays of liquid forms drops

by pneumatic atomization. In either technique, charging can be accomplished by one of

several procedures. High-potential electrodes can be placed in the area where the drops

form to induce a charge on the drops. Another procedure is to produce a corona discharge

so that the drops can be charged by ion impaction. The first procedure (induction charging)

charges them after they are formed. The first procedure, to induce or influence charging,

theoretically requires no electrical energy, and some actual values are noted later.

Figure 7 shows examples of induction charging using pneumatic atomization noz-

zles (mechanical atomization with pneumatic assistance). The first system (Fig. 7a) is

a standard commercial nozzle with inducer electrodes added. Note that these elec-

trodes can have the same charge or opposite charges and can also be at the same or

different voltage potentials. Bipolar charged drops would be produced using equal

voltages but different charges on the electrodes. A mixture of unipolar drops is gen-

erated using the same charge but different voltages on the electrodes. In one system,

the electrodes were placed 1.6 mm from the nozzle body and spaced 4.7 mm (center

to center) apart.

Amultinozzle induction charging system such as shown in Fig. 7b has been con-

structed using a pneumatic atomizer with a nonconducting body. The gas orifice diameter

was 7.5 mm.

In actual practice, current requirements of the inducer nozzles shown were about

1.2 µA per 100 V(root means square) for the single commercial test nozzle and about

0.2 µA per 100V for the multiple-nozzle system for inducer voltages up to about 350 V.

Reports on electrohydrodynamic spraying nozzles indicate that a potential of 45 kV is

3

used and requires about 0.25 kW energy per 1000 ft /min for charging. Corona drop

charging units operate at about 27 kV.