Page 257 - Air and Gas Drilling Manual

P. 257

6-2 Air and Gas Drilling Manual

used are treated fresh water, treated salt water (formation water), water based drilling

muds, diesel oil, oil based drilling muds, and crude oil (formation oil).

It is assumed that compressible gases can be approximated by the perfect gas

law. Further, it is assumed that the mixture of compressed gas and incompressible

fluid will be uniform and homogeneous. When the solid rock cuttings are added to

the mixture of compressible gas and incompressible fluid, the solid rock particles are

assumed to be uniform in size and density and will be distributed uniformly in the

mixture of gas and fluid. Also, it is assumed that the rock particles move with the

same velocity as circulating gas and fluid and that the resulting uniform mixtures

can be approximated by known basic fluid mechanics relationships [1].

The assumption of uniformity of the two or three phases in the mixtures is an

important issue in light of the technology developed for gas lift assisted oil

production [2, 3]. The aeration of oil (or other formation produced fluids) from the

bottom of a well with the flow of gas from the surface (down the annulus between

the casing and the production tubing) is somewhat similar to the aeration of fluid

and rock cuttings from the bottom of a well with a flow of gas and fluid from the

surface (down the inside of the drill string). However, in most oil production

situations the two phase flow takes place inside of the tubing. In the drilling

situation, the gas and fluid are injected together into the top of the drill string and

move together down the inside of the drill string, through the bit orifices or nozzles,

and then the resulting three phase flow (gas, fluid, and rock cuttings) moves up the

annulus to the surface. Thus, the geometry of flow for the two operations is quite

different and probably not comparable [4].

6.2 General Derivation

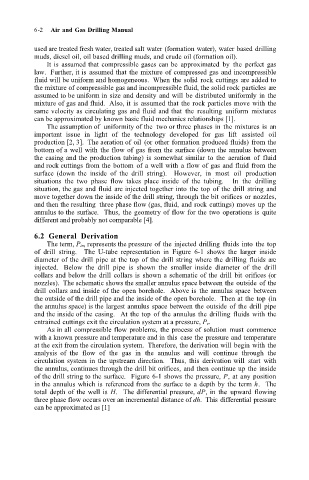

The term, P in, represents the pressure of the injected drilling fluids into the top

of drill string. The U-tube representation in Figure 6-1 shows the larger inside

diameter of the drill pipe at the top of the drill string where the drilling fluids are

injected. Below the drill pipe is shown the smaller inside diameter of the drill

collars and below the drill collars is shown a schematic of the drill bit orifices (or

nozzles). The schematic shows the smaller annulus space between the outside of the

drill collars and inside of the open borehole. Above is the annulus space between

the outside of the drill pipe and the inside of the open borehole. Then at the top (in

the annulus space) is the largest annulus space between the outside of the drill pipe

and the inside of the casing. At the top of the annulus the drilling fluids with the

entrained cuttings exit the circulation system at a pressure, P e.

As in all compressible flow problems, the process of solution must commence

with a known pressure and temperature and in this case the pressure and temperature

at the exit from the circulation system. Therefore, the derivation will begin with the

analysis of the flow of the gas in the annulus and will continue through the

circulation system in the upstream direction. Thus, this derivation will start with

the annulus, continues through the drill bit orifices, and then continue up the inside

of the drill string to the surface. Figure 6-1 shows the pressure, P, at any position

in the annulus which is referenced from the surface to a depth by the term h. The

total depth of the well is H. The differential pressure, dP, in the upward flowing

three phase flow occurs over an incremental distance of dh. This differential pressure

can be approximated as [1]